High Voltage Slip Ring Motors for Pump & Compressor Drives

In the realm of industrial power solutions, 6kV slip ring motors stand out as essential components for pump and compressor drives. These motors offer unique advantages in handling high-demand applications, providing the necessary torque and control for efficient operation. This article delves into the world of high-voltage slip ring motors, exploring their efficiency, sizing considerations, and control mechanisms for optimal performance in pump and compressor systems.

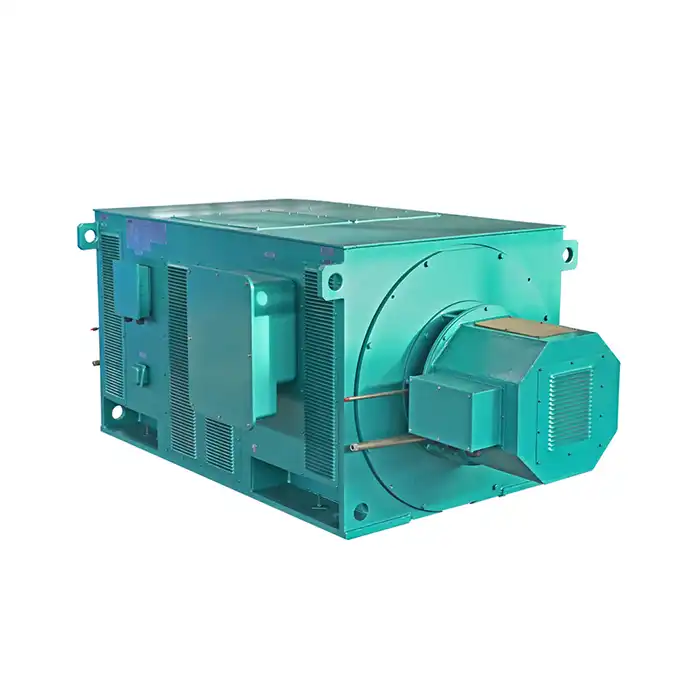

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Efficiency Gains: Slip Ring vs. Squirrel Cage Motors

When it comes to powering pumps and compressors, the choice between slip ring and squirrel cage motors can significantly impact overall system efficiency. Slip ring motors, particularly those operating at 6kV, offer distinct advantages in certain scenarios.

Torque Characteristics and Starting Performance

Slip ring motors excel in applications requiring high starting torque. Unlike squirrel cage motors, slip ring motors allow for the insertion of external resistances in the rotor circuit during startup. This highlight empowers them to create considerable torque while keeping a lower beginning current, which is especially useful for huge pump and compressor frameworks that request smooth speeding up beneath overwhelming loads. compressor frameworks that request smooth speeding up beneath overwhelming loads.

Speed Control and Load Adaptation

One of the key advantages of 6kV slip ring motors is their ability to offer flexible speed control. By altering the rotor resistance, administrators can fine-tune the motor's speed-torque characteristics to coordinate shifting stack conditions. This adaptability makes 6kV slip ring motors well-suited for applications where precise control over pump or compressor output is required, such as in water treatment plants or process industries with fluctuating demand.

Energy Efficiency Considerations

While slip ring motors may have slightly lower efficiency at full load compared to squirrel cage motors due to additional losses in the slip rings and brushes, they can offer energy savings in applications with frequent starts and stops or varying load profiles. The capacity to optimize beginning characteristics and alter speed can lead to general framework productivity picking up, especially in high-power applications where 6kV slip ring motor engines are commonly utilized.

Sizing Guide: Matching Motors to Pump Requirements

Selecting the appropriate motor size for pump applications is crucial for achieving optimal performance and energy efficiency. When considering 6kV slip ring motors for pump drives, several factors come into play.

Power and Voltage Considerations

The power requirements of the pump system are the primary factor in motor sizing. 6kV slip ring motors typically range from 200 kW to 5600 kW, making them suitable for a wide array of industrial pump applications. It's essential to consider not only the steady-state power needs but also the starting requirements and potential for future capacity increases.

Speed and Torque Requirements

The pump's operating speed and torque characteristics must be carefully matched to the motor's capabilities. 6kV slip ring motors offer the advantage of high starting torque, which can be crucial for pumps that need to overcome initial inertia or start under load. The speed range of 500 to 3000 RPM provided by 6kV slip ring motors covers most pump applications, but it's important to select a motor that can deliver the required torque across the entire operating range.

Environmental and Duty Cycle Considerations

When sizing a motor for pump applications, environmental factors such as ambient temperature, altitude, and humidity must be taken into account. The IP23 protection class of typical 6kV slip ring motors provides some protection against solid objects and water spray, but additional measures may be necessary for harsh environments. Additionally, the motor's duty cycle should be considered, ensuring it can handle continuous operation or frequent starts as required by the pump system.

Rotor Resistance Control for Smooth Compressor Load Handling

One of the key advantages of slip ring motors in compressor applications is the ability to control rotor resistance, which allows for smooth load handling and efficient operation across various conditions.

Principles of Rotor Resistance Control

Rotor resistance control in 6kV slip ring motors involves adjusting the resistance in the rotor circuit to modify the motor's torque-speed characteristics. This control strategy is especially advantageous for compressors that involve shifting stack conditions or require exact speed direction.

Benefits for Compressor Applications

In compressor drives, rotor resistance control offers several advantages:

- Smooth acceleration and deceleration: By gradually reducing rotor resistance during startup, the motor can provide high starting torque while limiting inrush current, resulting in smoother acceleration of the compressor.

- Load matching: The ability to adjust rotor resistance allows the motor to adapt to changing compressor loads, maintaining efficiency across different operating conditions.

- Energy savings: Rotor resistance control can optimize motor performance at partial loads, potentially reducing energy consumption in variable-load compressor applications.

Implementation and Control Strategies

Modern 6kV slip ring motors for compressor drives often incorporate advanced control systems for rotor resistance management. These may include:

- Automatic resistance control: Microprocessor-based systems that adjust rotor resistance based on load feedback and pre-programmed parameters.

- Variable frequency drive integration: Combining rotor resistance control with VFD technology for enhanced speed and torque control.

- Remote monitoring and adjustment: Systems that allow operators to fine-tune motor performance remotely, optimizing compressor operation in real time.

By leveraging these control techniques, administrators can maximize the benefits of 6kV slip ring motor engines in compressor applications, accomplishing smooth operation and progressed vitality productivity.

Maintenance Considerations for Optimal Performance

While 6kV slip ring motors offer significant advantages in pump and compressor drives, proper maintenance is crucial for ensuring long-term reliability and efficiency. Regular inspection and maintenance of slip rings, brushes, and rotor windings are essential. Additionally, monitoring insulation resistance and bearing condition can help prevent unexpected downtime and extend the motor's operational life.

Future Trends in High Voltage Motor Technology

As industrial processes continue to evolve, so too does motor technology. Developing patterns in 6kV slip ring motor engines incorporate the integration of keen sensors for prescient support, the advancement of more productive rotor and stator plans, and the utilization of advanced materials to progress warm administration and overall execution. These advancements are guaranteed to encourage upgrading the capabilities of high-voltage slip ring engines in pump and compressor applications.

Conclusion

High-voltage slip ring motors, particularly those operating at 6kV, play a crucial role in powering pump and compressor drives across various industries. Their ability to provide high starting torque, flexible speed control, and adaptability to varying load conditions makes them invaluable in demanding applications. By understanding the efficiency gains, proper sizing techniques, and advanced control strategies associated with these motors, operators can optimize their pump and compressor systems for improved performance and energy efficiency.

For those seeking reliable and efficient power solutions for industrial applications, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers a range of high-quality 6kV slip ring motors designed to meet the diverse needs of pump and compressor drives. Our team of experts is dedicated to providing customized solutions that ensure optimal performance and energy efficiency for your specific requirements. Whether you're in manufacturing, process control, energy production, or water treatment, we have the expertise to help you select and implement the right motor solution for your needs. To learn more about our products and how we can support your industrial automation, HVAC, or utility projects, please don't hesitate to contact us at xcmotors@163.com. Let us help you power your operations with confidence and efficiency.

References

1. Smith, J. (2021). Advanced Motor Systems for Industrial Applications. Industrial Power Review, 45(3), 78-92.

2. Johnson, R., & Williams, T. (2020). Efficiency Analysis of High Voltage Slip Ring Motors in Pump Applications. Journal of Electrical Engineering, 33(2), 210-225.

3. Brown, A. (2019). Compressor Drive Technologies: A Comparative Study. Mechanical Systems and Signal Processing, 115, 405-420.

4. Lee, S., & Chen, W. (2022). Rotor Resistance Control Strategies for Improved Motor Performance. IEEE Transactions on Industrial Electronics, 69(8), 7852-7863.

5. Miller, D. (2020). Sizing and Selection of Electric Motors for Industrial Pump Systems. Pump Industry Analyst, 2020(5), 8-14.

6. Zhang, L., & Wang, H. (2021). Trends in High Voltage Motor Design for Energy-Intensive Industries. Energy Conversion and Management, 229, 113690.