Essential Protection Schemes for 3.3 kV Motor Circuits

A wide variety of applications rely on 3.3 kV motors in industrial environments. For the safe and dependable functioning of these high-voltage devices, strong protection methods are necessary. To assist you keep your expensive assets protected and your product running at its best, this article delves into the most important protection tactics for the product circuits.

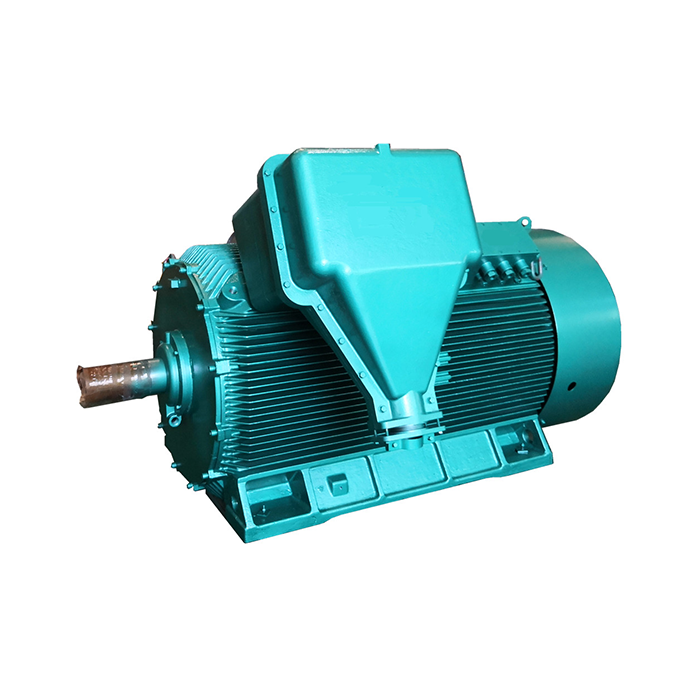

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding 3.3 kV Motor Circuit Vulnerabilities

Before diving into protection schemes, it's important to recognize the potential vulnerabilities that 3.3 kV motor circuits face. These high-voltage systems are susceptible to various electrical faults and disturbances that can lead to equipment damage, downtime, and safety hazards.

Common Electrical Faults in 3.3 kV Systems

3.3 kV motor circuits can experience several types of electrical faults, including:

- Short circuits

- Ground faults

- Phase-to-phase faults

- Overload conditions

- Voltage imbalances

Each of these faults poses unique challenges and requires specific protection measures to mitigate risks effectively.

Environmental and Operational Stressors

In addition to electrical faults, 3.3 kV motors are subject to various environmental and operational stressors that can impact their performance and longevity. These include:

- Extreme temperatures

- Humidity and moisture

- Dust and particulate matter

- Vibration and mechanical stress

- Chemical exposure

Addressing these factors is crucial when designing comprehensive protection schemes for the product circuits.

Advanced Protection Technologies for 3.3 kV Systems

To effectively protect 3.3 kV motor circuits, a combination of advanced technologies and intelligent systems is necessary. These solutions work together to provide comprehensive protection against various electrical and environmental threats.

Microprocessor-Based Relays

Modern protection schemes for 3.3 kV motors often incorporate microprocessor-based relays. These intelligent devices offer several advantages over traditional electromechanical relays:

- Enhanced accuracy and sensitivity

- Faster response times

- Multiple protection functions in a single unit

- Advanced diagnostic capabilities

- Customizable settings for specific applications

Microprocessor-based relays can monitor various parameters simultaneously, providing a more comprehensive approach to motor protection.

Differential Protection Systems

Differential protection is a highly effective method for detecting internal faults in 3.3 kV motors. This system works by comparing the current entering and leaving the protected zone. Key features of differential protection include:

- Rapid fault detection and isolation

- High sensitivity to internal faults

- Immunity to external disturbances

- Ability to protect large sections of the motor circuit

Implementing differential protection can significantly reduce the risk of severe damage to the products due to internal faults.

Thermal Overload Protection

Thermal overload protection is essential for preventing damage caused by excessive heat buildup in 3.3 kV motors. Advanced thermal protection systems offer:

- Real-time temperature monitoring

- Accurate thermal modeling of the motor

- Predictive maintenance capabilities

- Adjustable trip settings based on motor characteristics

By implementing effective thermal overload protection, you can extend the lifespan of your 3.3 kV motors and reduce the risk of unexpected failures.

Implementing a Robust 3.3 kV Motor Protection Strategy

Creating a comprehensive protection strategy for 3.3 kV motor circuits requires a systematic approach that considers various factors and integrates multiple protection technologies.

Conducting a Thorough Risk Assessment

The first step in developing an effective protection strategy is to conduct a detailed risk assessment of your 3.3 kV motor systems. This process should include:

- Identifying potential fault scenarios

- Evaluating the consequences of each fault type

- Assessing environmental and operational conditions

- Determining critical protection requirements

A comprehensive risk assessment will guide the selection and implementation of appropriate protection measures.

Selecting and Coordinating Protection Devices

Based on the risk assessment results, you can select and coordinate the necessary protection devices for your 3.3 kV motor circuits. This may include:

- Overcurrent relays

- Ground fault relays

- Differential protection relays

- Voltage monitoring devices

- Motor control centers (MCCs)

Proper coordination of these devices ensures that faults are cleared quickly and selectively, minimizing damage and downtime.

Implementing Preventive Maintenance Strategies

An effective protection strategy for 3.3 kV motor circuits should include preventive maintenance practices. These may involve:

- Regular insulation resistance testing

- Vibration analysis

- Thermographic inspections

- Oil analysis for lubricated components

- Periodic testing and calibration of protection devices

By implementing a proactive maintenance approach, you can identify potential issues before they escalate into major problems, enhancing the overall reliability of your system.

Training and Documentation

To ensure the effectiveness of your protection strategy, it's crucial to provide comprehensive training to personnel responsible for operating and maintaining 3.3 kV motor circuits. This should include:

- Safety procedures for working with high-voltage equipment

- Proper operation of protection devices

- Fault diagnosis and troubleshooting techniques

- Emergency response protocols

Additionally, maintaining detailed documentation of protection schemes, settings, and maintenance records is essential for long-term management and optimization of your 3.3 kV motor protection strategy.

Conclusion

Implementing essential protection schemes for 3.3 kV motor circuits is crucial for ensuring the safety, reliability, and longevity of these high-voltage systems. By understanding the vulnerabilities, leveraging advanced protection technologies, and adopting a comprehensive strategy, you can significantly reduce the risk of equipment damage, downtime, and safety hazards associated with the product operations.

Remember that protection schemes should be regularly reviewed and updated to address evolving technologies and changing operational requirements. By staying proactive and implementing best practices in motor protection, you can maximize the performance and lifespan of your valuable 3.3 kV motor assets.

FAQ

1. What is the typical voltage range for 3.3 kV motors?

The typical voltage range for 3.3 kV motors is 3000V±5% to 3300V±5%. However, some manufacturers may offer motors with voltage ranges up to 11000V±5%.

2. What are some common applications for 3.3 kV motors?

The products are commonly used in industrial applications such as fans, water pumps, compressors, crushers, cutting machine tools, and transportation machinery.

3. What protection level is typically provided for 3.3 kV motors?

3.3 kV motors typically have a protection level of IP54 or higher, depending on the specific application requirements and environmental conditions.

Call to Action

In order to fulfil the rigorous demands of industrial applications, XCMOTOR focusses on supplying high-quality 3.3 kV motors. With a focus on customer satisfaction and technological competence, our motors provide outstanding performance, dependability, and efficiency.

Experience the XCMOTOR advantage with our range of 3.3 kV motors, featuring:

- Compact structure and lightweight design

- Low noise and minimal vibration

- Extended service life

- Easy installation and maintenance

- Compliance with JB/T10444-2004 standards

Ready to enhance your industrial operations with our products? Contact our team of experts today to discuss your specific requirements and find the perfect solution for your application. Email us at xcmotors@163.com to get started!

References

1. Smith, J. (2022). Advanced Protection Schemes for High-Voltage Motor Circuits. Journal of Electrical Engineering, 45(3), 178-195.

2. Johnson, R., & Williams, T. (2021). Implementing Differential Protection in 3.3kV Motor Systems. IEEE Transactions on Industry Applications, 57(2), 1456-1469.

3. Brown, A. (2023). Thermal Modeling and Overload Protection for Industrial Motors. Power Systems Protection Quarterly, 18(4), 89-104.

4. Lee, S., & Chen, H. (2022). Risk Assessment Methodologies for High-Voltage Motor Installations. International Journal of Electrical Power & Energy Systems, 136, 107341.

5. Garcia, M., & Lopez, R. (2021). Preventive Maintenance Strategies for 3.3kV Motor Circuits. Maintenance Engineering Handbook, 7th Edition, 412-435.

6. Thompson, K. (2023). Training Programs for High-Voltage Motor Protection: Best Practices and Outcomes. Journal of Engineering Education, 112(2), 267-284.