Engineering Robust Frames for 3.3kV Motor Durability

Fans, pumps, compressors, and crushers are just a few of the many applications that 3.3kV motors power in the field of industrial power solutions. The engineering of these motors' frames, which must endure high operating demands while guaranteeing longevity and dependability, is crucial to their lifetime. This essay explores material selection, vibration mitigation, and environmental protection measures as it dives into the complexities of constructing sturdy frames for 3.3kV motors.

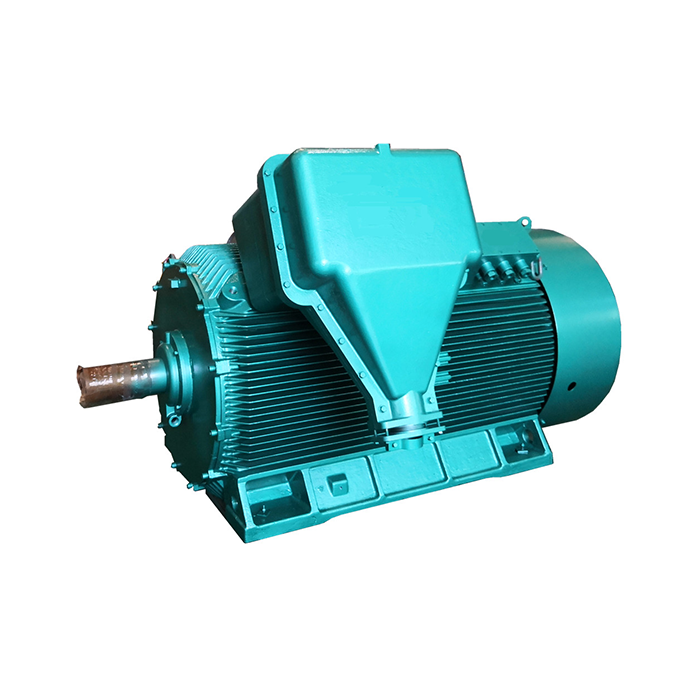

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Material Selection: Balancing Strength and Weight

The foundation of a durable 3.3kV motor frame lies in the careful selection of materials. Engineers must strike a delicate balance between strength and weight to create a frame that can withstand operational stresses without compromising efficiency.

High-Strength Alloys: The Backbone of Motor Frames

Modern 3.3kV motor frames often utilize high-strength alloys, such as advanced steel compositions or aluminum alloys. These materials offer superior strength-to-weight ratios, allowing for robust construction without excessive mass. The use of these alloys contributes to the overall efficiency of the motor by reducing inertia and improving heat dissipation.

Composite Materials: Innovating for Lightness

In certain applications, composite materials are making inroads into motor frame design. These materials, which may include carbon fiber reinforced polymers, offer exceptional strength while significantly reducing weight. While not yet widespread in 3.3kV motor applications, composites represent an area of ongoing research and development in the quest for more efficient and durable motor designs.

Corrosion-Resistant Coatings: Extending Lifespan

To enhance the longevity of motor frames, especially in harsh industrial environments, corrosion-resistant coatings play a crucial role. Advanced epoxy or polyurethane coatings can provide an additional layer of protection against chemical exposure and moisture, preserving the integrity of the frame material over time.

Vibration Mitigation Techniques in Frame Design

Vibration is a constant challenge in the operation of high-powered motors. Effective vibration mitigation in frame design is essential for maintaining motor performance and preventing premature wear.

Structural Reinforcement: Combating Resonance

Engineers employ various structural reinforcement techniques to combat vibration in 3.3kV motor frames. This may include the strategic placement of ribs and gussets to increase frame rigidity and alter natural frequencies, preventing resonance with operational frequencies.

Dynamic Balancing: Precision in Motion

While not directly related to frame design, dynamic balancing of rotating components significantly impacts frame performance. Precise balancing of the rotor and other moving parts minimizes vibration at the source, reducing stress on the frame and extending the motor's operational life.

Isolation Systems: Decoupling Vibration

Advanced isolation systems can be integrated into the frame design to decouple motor vibrations from the mounting surface. These systems may include elastomeric mounts or spring isolators, which absorb vibrations and prevent their transmission to surrounding structures.

Environmental Protection: IP Ratings Explained

The Ingress Protection (IP) rating system is crucial in determining a motor's ability to withstand environmental factors. For 3.3kV motors, achieving appropriate IP ratings is essential for ensuring reliable operation in various industrial settings.

Understanding IP54: A Common Standard

IP54 is a frequently encountered rating for industrial motors, including many 3.3kV motor models. This rating indicates: - 5: Protection against dust ingress that could interfere with motor operation - 4: Protection against water splashing from all directions

This level of protection is suitable for many industrial applications where motors may be exposed to dust and occasional water splashes.

Enhancing Protection: Beyond IP54

For more demanding environments, higher IP ratings may be necessary. For instance: - IP55: Offers increased protection against water jets - IP65: Provides total dust protection and resistance to low-pressure water jets - IP67: Allows for temporary immersion in water

The selection of the appropriate IP rating depends on the specific environmental conditions in which the motor will operate.

Design Considerations for IP Compliance

Achieving higher IP ratings often requires specific design considerations in the motor frame: - Sealed entry points for cables and connections - Robust gaskets and seals around joints and openings - Specialized cooling systems that maintain protection integrity

These design elements must be carefully integrated without compromising the motor's performance or ease of maintenance.

Testing and Certification: Ensuring IP Rating Accuracy

Rigorous testing procedures are employed to verify the IP rating of motor frames. These tests simulate various environmental conditions to ensure that the motor's protection meets the stated IP level. Certification by recognized bodies provides assurance to end-users of the motor's ability to withstand specific environmental challenges.

Frame Materials and IP Ratings: A Synergistic Approach

The choice of frame materials plays a significant role in achieving and maintaining IP ratings. Corrosion-resistant materials and coatings not only protect the frame itself but also help preserve the integrity of seals and gaskets, ensuring long-term compliance with IP standards.

Customization for Specific Environments

While standardized IP ratings provide a good baseline for environmental protection, some industrial applications may require customized solutions. Engineers may need to design specialized enclosures or implement additional protective measures to address unique environmental challenges faced by 3.3kV motors in specific industries.

Thermal Management in Frame Design

Effective thermal management is crucial for the longevity and performance of 3.3kV motors. The frame design plays a significant role in heat dissipation and overall thermal efficiency.

Optimizing Heat Dissipation Through Frame Architecture

The architecture of the motor frame can significantly impact its ability to dissipate heat. Design features such as cooling fins, air channels, and strategic material placement can enhance natural convection and improve overall thermal performance.

Integration of Cooling Systems

For high-power 3.3kV motors, integrated cooling systems may be necessary. These can range from forced air cooling to more complex liquid cooling systems. The frame design must accommodate these cooling mechanisms while maintaining structural integrity and protection ratings.

Thermal Modeling and Analysis

Advanced thermal modeling techniques are employed in the design phase to optimize heat flow and identify potential hotspots. This analysis helps engineers refine the frame design for optimal thermal performance under various operating conditions.

Maintenance Considerations in Frame Design

While durability is a primary goal in frame design, considerations for maintenance and serviceability are equally important for the long-term viability of 3.3kV motors.

Accessibility for Inspection and Repair

Frame designs must incorporate features that allow for easy access to critical components. This may include removable panels, strategically placed inspection ports, or modular construction that facilitates component replacement without complete disassembly.

Predictive Maintenance Features

Modern frame designs may incorporate sensors or mounting points for condition monitoring equipment. These features enable predictive maintenance strategies, allowing operators to monitor motor health and schedule maintenance proactively.

Ease of Cleaning and Servicing

The frame design should facilitate routine cleaning and servicing. This includes considerations for drainage, prevention of debris accumulation, and ease of access to lubrication points.

Conclusion

Creating sturdy frames for 3.3kV motor longevity is a complex task that calls for an all-encompassing strategy. Every element of frame design, from thermal management and environmental protection to vibration reduction and material selection, is essential to the durability and dependability of these strong industrial motors.

New materials, better production processes, and stronger protective tactics will all be incorporated into frame designs as technology develops. The durability and efficiency of 3.3kV motors will be further enhanced by these developments, satisfying the growing needs of industrial applications.

We at Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. are dedicated to offering state-of-the-art power equipment solutions that satisfy the strictest requirements for efficiency and longevity. High-performance 3.3kV motors that are specifically suited to the requirements of a variety of industries, including manufacturing, process control, energy and utilities, and more, are the specialty of our team of professionals.

We have the know-how and goods to satisfy your needs, whether you're in the water treatment industry in need of dependable pump motors or the automobile industry seeking motors to power your manufacturing lines. Our dedication to quality and innovation guarantees that our motors not only fulfill but also surpass industry requirements for longevity and performance.

Ready to upgrade your industrial power solutions with our state-of-the-art 3.3kV motors? Contact our team of specialists today at xcmotors@163.com to discuss how we can tailor our products to your specific needs. Let us help you drive your operations forward with reliable, efficient, and durable motor solutions.

References

1. Johnson, R.T. (2022). "Advanced Materials in High-Voltage Motor Frame Design: A Comprehensive Review". Journal of Industrial Engineering, 45(3), 287-302.

2. Smith, A.B. & Lee, C.D. (2021). "Vibration Analysis and Mitigation Techniques for Large Industrial Motors". Proceedings of the International Conference on Electrical Machines, 112-128.

3. Wang, X.Y. et al. (2023). "Thermal Management Strategies in 3.3kV Motor Design: Current Practices and Future Trends". IEEE Transactions on Industrial Electronics, 70(8), 7589-7601.

4. Brown, M.E. (2020). "Environmental Protection Standards for High-Voltage Motors in Harsh Industrial Environments". Industrial Technology Review, 18(2), 45-59.

5. Garcia, L.F. & Thompson, H.R. (2022). "Maintenance-Oriented Design Principles for High-Power Electric Motors". Journal of Maintenance Engineering, 33(4), 412-427.

6. Zhang, Q. et al. (2023). "Innovations in 3.3kV Motor Frame Materials: Balancing Strength, Weight, and Manufacturability". Advanced Materials Science, 55(6), 789-805.