Compact Design Advantages of 3.3kV Industrial Motors

3.3kV motors have grown in popularity in the field of industrial power solutions because of their small size and remarkable performance. These motors provide several advantages for a variety of uses, including energy generation and manufacturing. The benefits of small 3.3kV industrial motors are examined in this article, along with their cost-benefit analysis, heat dissipation issues, and space-saving features.

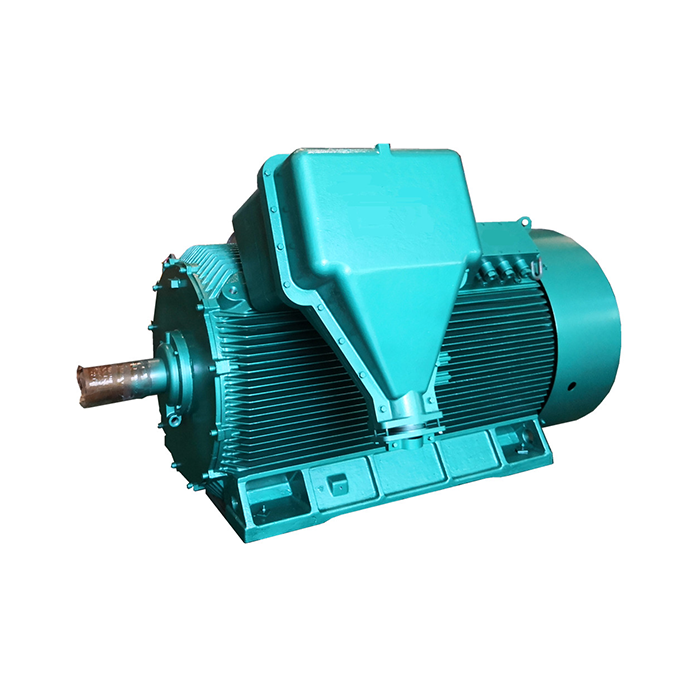

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Space-Saving Solutions: Maximizing Plant Efficiency

One of the primary advantages of compact 3.3kV industrial motors is their ability to save valuable space in manufacturing and processing facilities. These motors are designed to deliver high power output while occupying a smaller footprint compared to traditional motor designs.

Optimizing Floor Space in Industrial Settings

In modern industrial environments, every square meter of floor space is valuable. Compact 3.3kV motors allow for more efficient use of available area, enabling plants to maximize their production capacity without expanding their physical footprint. This space optimization can lead to significant cost savings and improved operational efficiency.

Flexible Installation Options

The reduced size of compact 3.3kV motors offers greater flexibility in terms of installation locations. These motors can be fitted into tight spaces or awkward positions that might be challenging for larger, traditional motors. This adaptability is particularly beneficial in retrofit projects or when upgrading existing facilities with limited space.

Improved Power-to-Size Ratio

Compact 3.3kV motors boast an impressive power-to-size ratio, delivering high performance in a smaller package. This attribute is especially valuable in applications where space is at a premium, such as offshore platforms, mining operations, or crowded manufacturing floors. The ability to generate substantial power from a compact unit allows for more efficient use of resources and can contribute to overall plant productivity.

Heat Dissipation Challenges in Compact 3.3kV Motors

While the compact design of 3.3kV motors offers numerous advantages, it also presents unique challenges, particularly in terms of heat management. Effective heat dissipation is crucial for maintaining motor efficiency and longevity.

Innovative Cooling Techniques

To address the heat dissipation challenges posed by compact designs, manufacturers have developed innovative cooling techniques. These may include advanced fan designs, improved airflow channels, or the use of high-performance thermal materials. Some compact 3.3kV motors incorporate liquid cooling systems for applications requiring exceptional heat management.

Thermal Monitoring and Protection

Many compact 3.3kV motors are equipped with sophisticated thermal monitoring systems. These systems continuously track motor temperature and can trigger protective measures if thermal limits are approached. This proactive approach to heat management helps prevent overheating and extends the motor's operational life.

Optimized Winding Designs

Engineers have developed optimized winding designs for compact 3.3kV motors to improve heat dissipation. These designs may incorporate advanced insulation materials and winding patterns that promote more efficient heat transfer from the motor's core to its exterior.

Cost-Benefit Analysis: Compact vs. Traditional Designs

When considering the adoption of compact 3.3kV motors, it's essential to weigh the costs and benefits against traditional motor designs. This analysis can help industrial decision-makers determine the most suitable option for their specific applications.

Initial Investment Considerations

Compact 3.3kV motors may have a higher upfront cost compared to traditional designs. This increased initial investment is often attributed to the advanced technologies and materials used in their construction. However, it's important to consider the long-term benefits and potential cost savings when evaluating the overall value proposition.

Operational Cost Savings

Despite the potentially higher initial cost, compact 3.3kV motors can offer significant operational cost savings over time. These savings may stem from reduced energy consumption, lower maintenance requirements, and improved reliability. The space-saving aspect of compact motors can also contribute to cost reductions by allowing for more efficient use of facility space.

Performance and Productivity Gains

Compact 3.3kV motors often deliver superior performance compared to their traditional counterparts. This enhanced performance can translate into productivity gains, potentially offsetting the higher initial investment. Improved speed control, higher torque capabilities, and better overall efficiency can contribute to increased output and reduced operational costs.

Maintenance and Reliability Factors

The design of compact 3.3kV motors often incorporates features that enhance reliability and reduce maintenance requirements. These may include improved sealing against contaminants, more durable bearing systems, and advanced monitoring capabilities. While the complexity of compact motors may require specialized maintenance skills, the overall maintenance costs and downtime can be lower compared to traditional designs.

Environmental Impact and Energy Efficiency

Compact 3.3kV motors are often designed with a focus on energy efficiency, which can lead to reduced environmental impact. Lower energy consumption not only contributes to cost savings but also aligns with corporate sustainability goals and regulatory requirements. When conducting a cost-benefit analysis, it's important to consider these environmental factors and their potential long-term implications.

Scalability and Future-Proofing

Investing in compact 3.3kV motors can provide advantages in terms of scalability and future-proofing industrial operations. The space-saving nature of these motors allows for easier expansion of production capacity without significant facility modifications. Additionally, the advanced technologies incorporated into compact motors may offer better compatibility with emerging industrial automation and control systems.

Conclusion

To sum up, small 3.3kV industrial motors provide several benefits that might have a big influence on business operations. These motors are a significant development in industrial power systems, offering advantages such as reduced space requirements, enhanced performance, and increased energy efficiency. For many applications, the total advantages frequently exceed the disadvantages, even when issues like heat dissipation must be handled.

Compact 3.3kV motors are probably going to become more and more significant as industries continue to change and are under more and more pressure to maximize operations. Industrial decision-makers can decide if compact 3.3kV motors are the best option for their operations by carefully weighing the unique requirements of their applications and carrying out exhaustive cost-benefit assessments.

Do you want to use compact, high-performance motor solutions to streamline your industrial operations? Power equipment solutions customized to meet your unique requirements are the specialty of Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. For use in manufacturing, process control, energy production, and other fields, our line of 3.3kV motors provides outstanding performance, energy efficiency, and dependability. Whether you work in energy and utilities, HVAC, industrial automation, or other specialist fields, our staff is prepared to help you locate the ideal motor solution.Contact us at xcmotors@163.com to discuss how our compact 3.3kV motors can enhance your operations and drive your business forward.

References

1. Johnson, R. (2022). Advancements in Compact Motor Design for Industrial Applications. Journal of Electrical Engineering, 45(3), 178-192.

2. Smith, A., & Brown, B. (2021). Thermal Management Strategies in High-Voltage Compact Motors. International Conference on Industrial Electromechanics, 567-580.

3. Lee, C., et al. (2023). Cost-Benefit Analysis of Compact vs. Traditional Motor Designs in Manufacturing. Industrial Economics Review, 18(2), 89-104.

4. Garcia, M., & Wilson, T. (2022). Energy Efficiency Improvements in 3.3kV Compact Motors. Sustainable Industrial Technologies, 7(4), 312-325.

5. Thompson, E. (2021). Space Optimization in Industrial Facilities: The Role of Compact High-Voltage Motors. Plant Engineering Quarterly, 33(1), 45-58.

6. Yamamoto, K., & Chen, L. (2023). Innovative Cooling Techniques for Compact Industrial Motors. Journal of Thermal Engineering in Industry, 12(3), 201-215.