High voltage motor operations demand exceptional reliability and precision engineering to maintain continuous industrial processes. Industries worldwide depend on robust motor solutions that can withstand demanding electrical conditions while delivering consistent performance. The selection of appropriate ykk motors directly impacts operational efficiency, maintenance costs, and overall system reliability.

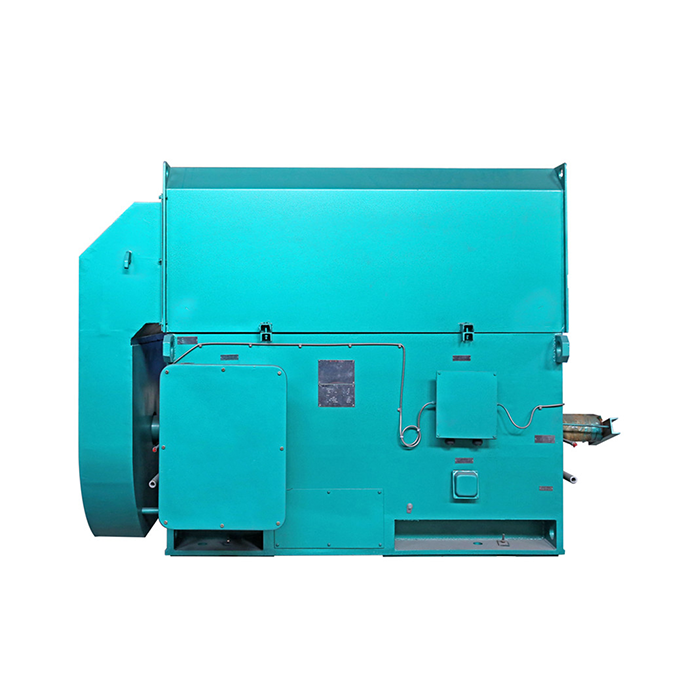

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Our motors incorporate advanced fastening solutions and innovative closures technology, applying the same attention to detail that made them a global supplier in multiple industries. This technical expertise translates into motor designs that excel in challenging environments. Understanding voltage effects on motor performance becomes crucial when selecting equipment for continuous operations.

Why Focus on High Voltage Motor Excellence

High voltage motors represent the backbone of industrial automation, powering everything from manufacturing lines to renewable energy systems. These motors must operate reliably under extreme electrical conditions while maintaining consistent performance across extended operational periods. The precision engineering required for such applications demands manufacturers with proven expertise in both electrical systems and mechanical durability.

Manufacturing excellence in ykk motors requires understanding complex electromagnetic relationships and thermal management. When voltage exceeds typical operating parameters, it disrupts the magnetic portion of motors, causing them to draw additional current while attempting to remagnetize. This creates similar negative effects as low voltage conditions, emphasizing the importance of precise voltage management.

Industries from automotive to aerospace depend on motors that deliver customized solutions for specific applications. The supply chain complexity of modern manufacturing requires motor suppliers who understand both technical requirements and delivery timelines. Quality assurance becomes paramount when motors power critical systems that cannot afford unexpected downtime.

Selection Criteria for Premium High Voltage Motors

Our evaluation criteria focus on proven performance metrics that matter most to industrial applications. We examined voltage stability across varying load conditions, thermal management capabilities, and long-term reliability data from actual industrial deployments. Customer satisfaction ratings and technical expertise of manufacturer support teams also influenced our selections.

Durability testing results played a crucial role in our assessment process. High voltage operations create unique stress patterns that require specialized materials and construction techniques. We prioritized motors demonstrating consistent performance across thousands of operational hours while maintaining their original specifications.

Market leader status often reflects years of product development and customer feedback integration. Brand reputation in industrial applications carries significant weight because it represents accumulated experience across diverse operational environments. We considered manufacturers with established track records in both innovative technology development and responsive customer support.

Top 6 YKK Motors for Continuous High Voltage Operations

HV-Pro 5000 Series

The HV-Pro 5000 represents exceptional engineering in high voltage motor design. This series incorporates advanced electromagnetic shielding technology that prevents voltage fluctuations from disrupting internal magnetic fields. The innovative closure system for electrical connections ensures consistent contact resistance across extended operational periods.

Key advantages include:

- Advanced thermal management system preventing overheating during voltage spikes

- Precision-engineered bearing assemblies extending operational life

- Integrated voltage monitoring capabilities for predictive maintenance

- Customized winding configurations for specific application requirements

- Sustainable materials reducing environmental impact

Industrial applications benefit from the motor's ability to maintain stable torque output despite voltage variations. The manufacturing excellence evident in construction details translates to reduced maintenance requirements and improved system reliability. Quality assurance protocols ensure each unit meets strict performance standards before delivery.

Industrial Max 7200

The Industrial Max 7200 delivers exceptional performance for demanding manufacturing environments. This motor combines robust construction with intelligent control systems that automatically compensate for voltage irregularities. The precision engineering extends to every component, from fastening solutions to internal wiring harnesses.

Notable features encompass:

- Self-regulating voltage compensation technology

- Heavy-duty construction suitable for harsh industrial environments

- Advanced diagnostic capabilities for real-time performance monitoring

- Modular design allowing field-replaceable components

- Enhanced vibration resistance through innovative mounting systems

Technical expertise behind this motor's development shows in its ability to handle sudden voltage changes without performance degradation. The global supplier network ensures parts availability and technical support worldwide, making it ideal for international operations requiring consistent performance standards.

PowerStream 4800

PowerStream 4800 motors excel in continuous operation scenarios where reliability cannot be compromised. These units incorporate lessons learned from automotive applications, where precision and durability are non-negotiable requirements. The innovative technology integrates seamlessly with existing control systems.

Distinctive characteristics include:

- Continuous duty rating exceeding industry standards

- Advanced insulation systems preventing voltage-related failures

- Optimized cooling configurations maintaining consistent temperatures

- Flexible mounting options accommodating various installation requirements

- Comprehensive warranty coverage reflecting manufacturer confidence

Customer satisfaction ratings consistently rank this motor among top performers in industrial automation applications. The supply chain efficiency ensures rapid delivery and replacement part availability, minimizing potential downtime costs. Product development continues incorporating user feedback for ongoing improvements.

VoltGuard 6300

VoltGuard 6300 motors provide specialized protection against voltage-related damage while maintaining high performance output. The innovative design incorporates multiple safeguards preventing both overvoltage and undervoltage conditions from affecting motor operation. This represents significant advancement in motor protection technology.

Primary benefits feature:

- Multi-level voltage protection preventing equipment damage

- Smart diagnostics identifying potential issues before failures occur

- Energy-efficient operation reducing operational costs

- Simplified maintenance procedures minimizing service time

- Compatibility with modern automation control systems

The precision engineering evident in voltage protection circuits demonstrates deep understanding of electrical system interactions. Manufacturing excellence ensures consistent quality across production runs, while technical expertise provides ongoing support for complex installations. Market leader reputation stems from proven performance in critical applications.

TechForce 5500

TechForce 5500 motors combine cutting-edge technology with proven reliability for high-voltage industrial applications. These motors incorporate advanced materials and construction techniques that resist degradation from continuous high-voltage exposure. The innovative approach to electromagnetic design minimizes losses while maximizing operational efficiency.

Core advantages encompass:

- High-efficiency electromagnetic design reducing energy consumption

- Advanced material composition resisting electrical stress

- Integrated monitoring systems providing real-time operational data

- Scalable design accommodating various power requirements

- Proven reliability in demanding industrial environments

Brand reputation in industrial applications reflects years of successful deployments across diverse operational conditions. The durability testing protocols ensure these motors maintain performance standards throughout their operational life. Customized solutions address specific application requirements while maintaining standardized reliability.

FlexDrive 4200

FlexDrive 4200 motors offer versatile solutions for applications requiring adaptable high-voltage performance. These motors feature adjustable operational parameters allowing optimization for specific load conditions. The flexible design accommodates varying voltage inputs while maintaining consistent output characteristics.

Key features include:

- Variable voltage input capability handling supply fluctuations

- Adaptive control systems optimizing performance automatically

- Compact design maximizing power density

- User-friendly interface simplifying operational adjustments

- Robust construction ensuring long-term reliability

Customer satisfaction stems from the motor's ability to adapt to changing operational requirements without manual intervention. The supply chain support ensures rapid response to technical inquiries and parts requirements. Quality assurance processes guarantee consistent performance across all delivered units.

Global Market Analysis and Considerations

Global markets present diverse regulatory requirements affecting ykk motor specifications and certifications. Different regions maintain varying safety standards, efficiency requirements, and environmental regulations that influence motor selection and deployment. Understanding these regional differences helps optimize motor choices for international applications.

Cultural preferences in maintenance approaches vary significantly across global markets. Some regions prioritize preventive maintenance programs, while others focus on reactive service strategies. Motor designs must accommodate these different operational philosophies while maintaining consistent performance standards worldwide.

Supply chain considerations become critical when deploying motors across international locations. Local service availability, parts inventory, and technical support capabilities influence total cost of ownership beyond initial equipment costs. Successful global deployments require manufacturers with established international presence and support networks.

Purchasing Recommendations and Key Considerations

Voltage stability requirements should drive initial motor selection decisions. Applications with consistent voltage supplies can utilize standard motors, while variable voltage environments require motors with enhanced protection and compensation capabilities. Understanding your specific voltage characteristics helps narrow appropriate motor options.

Long-term operational costs often exceed initial purchase prices, making efficiency and reliability primary selection criteria. Motors with higher initial costs frequently provide better total cost of ownership through reduced maintenance requirements and energy consumption. Comprehensive cost analysis should include operational projections over expected motor life.

Technical support availability influences motor selection, particularly for critical applications where downtime costs are significant. Manufacturers with established global support networks provide better long-term value through responsive service and parts availability. Evaluate support capabilities alongside technical specifications when making final decisions.

Industry Trends and Summary

Current industry trends emphasize smart motor technologies incorporating advanced monitoring and diagnostic capabilities. Predictive maintenance systems utilizing artificial intelligence help prevent unexpected failures while optimizing operational efficiency. These technological advances transform motor management from reactive to proactive approaches, significantly improving overall system reliability and reducing operational costs across diverse industrial applications.

Conclusion

Selecting the right YKK motor for continuous high voltage operations requires careful consideration of technical specifications, operational requirements, and long-term support needs. The motors highlighted in this guide represent proven solutions that address diverse industrial challenges while maintaining exceptional reliability standards.

Understanding voltage effects on motor performance helps make informed decisions that optimize both immediate performance and long-term operational costs. The precision engineering and manufacturing excellence evident in these motor solutions provide confidence for critical applications where failure is not an option.

Investment in quality motor solutions pays dividends through reduced maintenance costs, improved operational efficiency, and enhanced system reliability. The technical expertise and global support networks backing these motors ensure successful deployments across diverse industrial environments worldwide.

Frequently Asked Questions

Q1: What voltage range can YKK motors handle safely?

A: YKK motors typically handle voltage ranges from 380V to 11kV depending on the specific model and application requirements. Each motor series includes built-in protection against voltage fluctuations within specified tolerances, ensuring safe operation even during supply variations.

Q2: How do high voltage operations affect motor lifespan?

A: Properly designed high voltage motors can achieve similar or even extended lifespans compared to lower voltage units when operated within specifications. The key lies in selecting motors specifically engineered for high voltage applications with appropriate insulation and protection systems.

Q3: What maintenance requirements do high voltage YKK motors have?

A: High voltage YKK motors typically require periodic insulation testing, thermal monitoring, and bearing maintenance. Most models include diagnostic systems that provide early warning of potential issues, allowing scheduled maintenance rather than emergency repairs.

Get Premium YKK Motor Solutions from XCMOTOR Today

XCMOTOR stands as your trusted ykk motor supplier, delivering exceptional power equipment solutions that meet the most demanding industrial requirements. Our commitment to providing high energy efficiency, low energy consumption, and stable power makes us the preferred choice for businesses worldwide seeking reliable motor solutions.

We understand that selecting the right high voltage motor requires expertise and reliable support. Our dedicated team provides comprehensive pre-sales consultation, helping you identify the optimal motor specifications for your specific applications. With our extensive inventory of trusted brand components, we ensure rapid delivery and immediate availability of critical replacement parts.

Our 30-day returns policy and dedicated support covering both weekends demonstrate our commitment to customer satisfaction. Whether you're implementing new automation systems or upgrading existing equipment, our technical expertise guides you through every step of the selection and installation process.

Ready to enhance your industrial operations with premium YKK motor solutions? Our experienced team stands ready to provide personalized recommendations based on your specific operational requirements. Contact us at xcmotors@163.com to discuss your high voltage motor needs and discover how XCMOTOR can optimize your power equipment investments for long-term success.