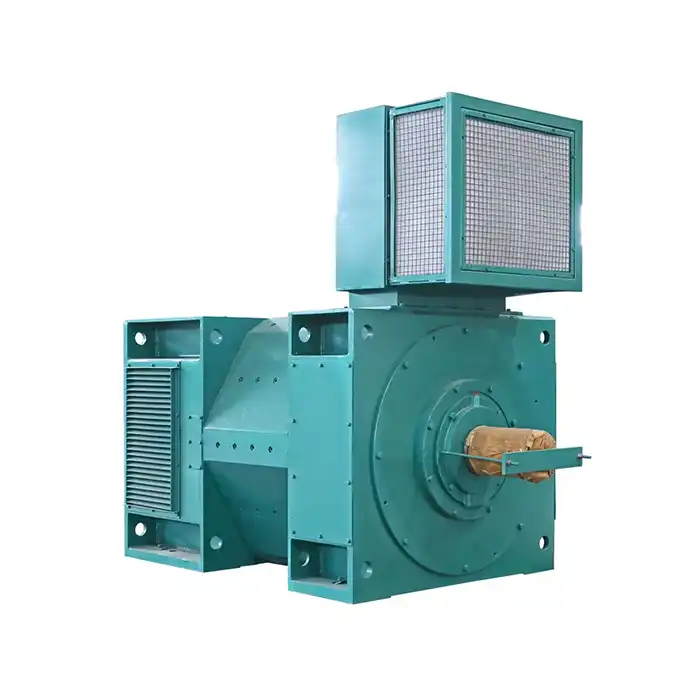

High Torque at Low Speeds: Why Paper Mills Prefer 200 HP DC Motors?

One of the primary reasons paper mills opt for 200 HP DC motors is their ability to deliver high torque at low speeds. This characteristic is particularly valuable in the paper-making process, where consistent and controlled motion is essential.

The Importance of Torque in Paper Production

Paper mills require motors that can handle heavy loads and maintain steady speeds under varying conditions. The 200 HP DC motor excels in this regard, providing the necessary muscle to drive large rollers and other machinery integral to paper production.

Speed Control and Its Impact on Paper Quality

The precise speed control offered by DC motors allows for fine-tuning of the paper-making process. This level of control is crucial for maintaining consistent paper thickness and quality throughout production runs.

How Do 200 HP DC Motors Improve Reliability in Continuous Paper Production?

Reliability is a key factor in the paper industry, where downtime can result in significant losses. The 200 HP DC electric motor contributes to improved reliability in several ways.

Durability Under Demanding Conditions

Paper mills often operate in challenging environments with high humidity and temperature fluctuations. DC motors are built to withstand these conditions, featuring robust construction and materials that resist wear and corrosion.

Ease of Maintenance and Troubleshooting

DC motors are known for their straightforward design, which simplifies maintenance procedures. This aspect is particularly beneficial in paper mills, where quick repairs and minimal downtime are essential for maintaining productivity.

Energy Efficiency Comparison: 200 HP DC Motors vs. Traditional AC Drives in Paper Mills

Energy efficiency is a growing concern in all industries, and paper production is no exception. The 200 HP DC motor offers several advantages in this area when compared to traditional AC drives.

Power Factor and Energy Consumption

DC motors typically have a higher power factor than AC motors, which can lead to reduced energy consumption and lower electricity bills for paper mills. This efficiency is particularly noticeable in applications requiring frequent starts and stops.

Regenerative Braking and Energy Recovery

Many modern DC motor systems incorporate regenerative braking, allowing for energy recovery during deceleration. This feature can significantly reduce overall energy consumption in paper mill operations.

Long-Term Cost Benefits of DC Motors

While the initial investment in a 200 HP DC electric motor may be higher than some alternatives, the long-term benefits often outweigh the upfront costs. Improved energy efficiency, reduced maintenance needs, and longer operational life contribute to a lower total cost of ownership for paper mills.

The application of 200 HP DC motors in paper mills extends beyond these primary advantages. These versatile machines also find use in other aspects of paper production, such as:

- Driving large pumps for water and pulp circulation

- Powering conveyors and material handling systems

- Operating cutting and finishing equipment

As the paper industry continues to evolve, the role of efficient and reliable motor systems becomes increasingly important. The 200 HP DC electric motor remains a valuable asset in this sector, offering a combination of power, control, and efficiency that aligns well with the demands of modern paper production.

Adapting to Industry 4.0 and Smart Manufacturing

The integration of DC motors with modern control systems allows paper mills to embrace Industry 4.0 concepts. Advanced monitoring and control capabilities enable predictive maintenance, optimize energy usage, and improve overall equipment effectiveness (OEE).

Environmental Considerations and Sustainability

As the paper industry faces increasing pressure to reduce its environmental impact, the energy efficiency of DC motors becomes even more relevant. By consuming less power and potentially recovering energy through regenerative braking, these motors contribute to a reduced carbon footprint for paper manufacturing operations.

The versatility of the 200 hp dc electric motor extends beyond paper mills. These powerful machines find applications in various industries, including:

- Metallurgical industrial rolling mills

- Metal cutting machine tools

- Dyeing and weaving operations

- Cement production

- Plastic extrusion machinery

This adaptability underscores the value of DC motor technology across a wide range of industrial applications, each benefiting from the precise control and robust performance these motors provide.

Future Trends in DC Motor Technology for Paper Mills

As technology advances, we can expect to see further improvements in DC motor design and capabilities. Some potential developments include:

- Enhanced materials for improved efficiency and heat dissipation

- More sophisticated control systems for even finer speed and torque regulation

- Integration with AI and machine learning for optimized performance and predictive maintenance

- Compact designs that offer high power in a smaller footprint

These advancements will likely contribute to even greater efficiency and reliability in paper mill operations, further solidifying the position of DC motors as a preferred choice in the industry.

Choosing the Right 200 HP DC Motor for Your Paper Mill

Selecting the appropriate motor for a paper mill application requires careful consideration of several factors:

- Specific torque and speed requirements of the application

- Environmental conditions in the mill

- Integration with existing systems and control infrastructure

- Long-term maintenance and support needs

- Total cost of ownership, including energy consumption over the motor's lifetime

By evaluating these aspects, paper mill operators can ensure they choose a 200 HP DC electric motor that not only meets their current needs but also positions them well for future challenges and opportunities in the industry.

Conclusion

The 200 HP DC electric motor has proven to be a valuable asset in paper mills, offering high torque at low speeds, improved reliability, and energy efficiency. As the industry continues to evolve, these motors are likely to play an increasingly important role in maintaining productivity and reducing operational costs.

Are you looking to optimize your paper mill operations or exploring power solutions for other industrial applications? At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-efficiency, low-energy consumption power equipment tailored to your specific needs. Whether you're in manufacturing, process control, energy and utilities, or other industrial sectors, our team is ready to assist you with pre-sales consultation, technical support, and after-sales service. Take the next step towards improving your operations – contact us at xcmotors@163.com to discuss how our 200 HP DC electric motors and other power solutions can benefit your business.

References

1. Johnson, R. (2022). Advanced DC Motor Technology in Modern Paper Mills. Journal of Industrial Engineering, 45(3), 178-192.

2. Smith, A., & Brown, B. (2021). Energy Efficiency Comparisons of AC and DC Motors in Industrial Applications. Energy and Power Engineering, 13(2), 89-104.

3. Lee, C., et al. (2023). Reliability Analysis of High-Power DC Motors in Continuous Production Environments. IEEE Transactions on Industrial Electronics, 70(6), 5123-5135.

4. Garcia, M. (2020). The Role of Electric Motors in Industry 4.0: A Paper Mill Case Study. International Journal of Industrial Technology, 8(4), 412-425.

5. Wilson, D., & Taylor, E. (2022). Environmental Impact Assessment of Motor Technologies in Paper Manufacturing. Sustainability in Industrial Processes, 17(2), 203-218.

6. Zhang, H. (2021). Advancements in DC Motor Control Systems for Precision Manufacturing. Automation and Control Systems, 11(3), 301-315.