6600V Motor for Oil & Gas: China Supply Options

Most of the time, the oil and gas industry works in some of the harshest places on Earth. Because of this, the tools they use have to be able to handle rough circumstances and still do their best. These rules are very strict for 6600V motors in this field because they are used in very important ways.

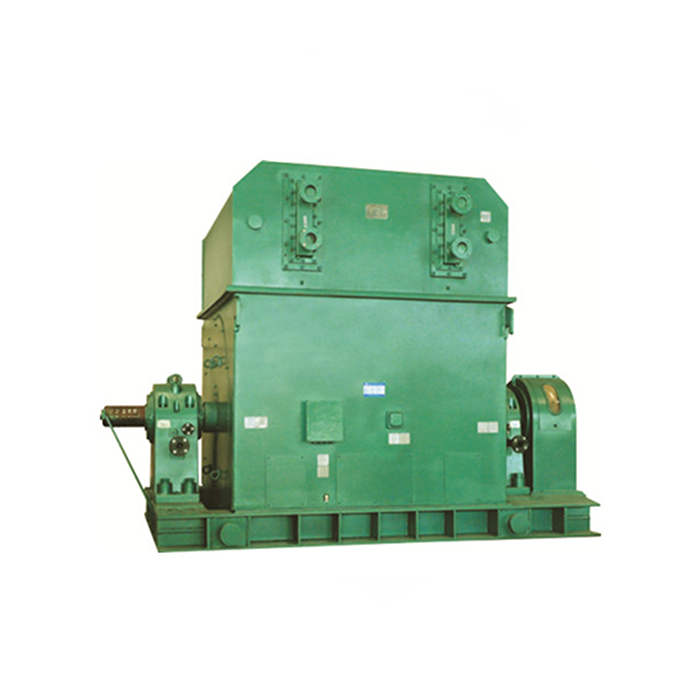

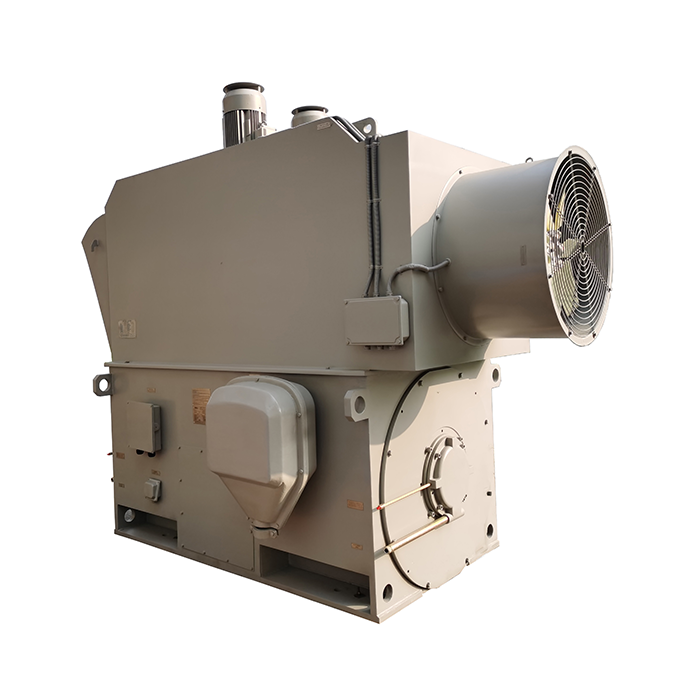

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Harsh Environmental Factors

A lot of the time, oil and gas work is done in remote places where the weather is bad. The temperatures of these motors have to be able to work well in places as hot as the desert and as cold as the arctic. They also need to be able to handle a lot of dust and sand in deserts and corrosion from saltwater in sites that are out at sea.

Continuous Operation Demands

In order to get oil and gas out of the ground, the machinery has to be able to run nonstop for a long time. In this field, 6600V motors are expected to work seven days a week, 24 hours a day. They don't get much time off for maintenance. All the parts are under a lot of stress because of the constant duty cycle, so they need to be well thought out and made.

Safety in Hazardous Atmospheres

When used in oil and gas, one of the most important things motors must be able to do is work carefully in places that could blow up. There are flammable gases and vapors in the air, so all electrical equipment, even high-voltage motors, has to be made and tested to make sure that sparks can't get into it.

Specialized Features of 6600V Motors for Explosive Atmospheres

6600V motors have a number of special features that make sure they work safely and reliably in dangerous environments so they can handle the tough conditions of oil and gas activities.

Explosion-Proof Enclosures

An explosion-proof shelter is the best way to keep something from starting a fire. These tough housings are made to keep any blast inside, so it doesn't spread to the air around them. Most of the time, the enclosures are made of cast iron or steel that has been manufactured. They have carefully designed flame paths that keep the gases that escape below the ignition temperature of the air around them.

Enhanced Insulation Systems

For oil and gas uses, high-voltage motors use advanced insulation systems to handle the electrical stresses that come with running at 6600V. A lot of the time, these systems use vacuum pressure impregnation (VPI) methods and special resins that are very resistant to chemicals, water, and partial release.

Thermal Protection Mechanisms

Comprehensive thermal protection is built into these motors to keep them from overheating in tough working situations. Usually, this includes RTD (Resistance Temperature Detector) sensors built into the stator windings and bearings. These are linked to tracking systems that can sound alarms or shut down the machine if temperature limits are crossed.

Ingress Protection (IP) Ratings

For oil and gas uses, motors need to have high IP ratings to keep out dust and water. Most motors have an IP rating of 56 or higher, which means they can handle strong water jets and are dust-tight, which is important for keeping them reliable in harsh settings like the desert or the ocean.

Mapping China's Supply Chain for Oil & Gas Grade Electrical Equipment

China has become a major player in the global supply chain for electrical tools used in oil and gas, such as 6600V motors. Companies that want to find reliable and affordable options need to understand this supply chain.

Major Manufacturing Hubs

Several places in China have become major centers for making high-voltage motors that can be used in oil and gas industries. A lot of factories that can make explosion-proof 6600V motors are located in cities like Shanghai, Guangzhou, and Shenyang. These hubs have established supply chains, pools of skilled workers, and are close to big ports, which makes exporting easier.

Raw Material Sourcing

Chinese companies have strong supply chains for important raw materials like electrical steel of good quality, copper for windings, and special insulation materials. Some parts may have to be imported to meet certain quality standards, but most are made in the United States, which helps keep prices low.

Quality Control Processes

To meet foreign standards, major Chinese manufacturers have put in place strict quality control systems. This includes in-house testing facilities for routine and type tests according to IEC standards. This makes sure that 6600V motors can handle the tough conditions of oil and gas uses.

Vetting Manufacturers for Safety Certifications and Field Experience

If you want to buy 6600V motors from China for oil and gas applications, you need to make sure that the makers follow international safety standards and have a history of good performance in the field.

International Certifications

Manufacturers of explosion-proof motors in China that you can trust will have approvals from well-known international groups. Look for badges of honor like:

- ATEX (World)

- The International IECEx

- UL (North America)

- CNEX (China)

These labels show that the maker's goods have been checked out and given the all-clear to be used in dangerous places.

Track Record in Oil & Gas Projects

A very important factor is having experience providing motors for oil and gas projects. Find out about the manufacturer's past projects by asking for case studies or references from setups that were done in similar situations. This can give them useful information about how reliable and well their 6600V motors work in real life.

Technical Capabilities and Support

Check out the manufacturer's technical skills, such as their engineering know-how, customization choices, and customer service after the sale. If a maker has a strong technical team, they can help you choose the right motor specifications for your needs and provide ongoing support for as long as the product is in use.

Selecting a Dependable 6600V Motor Partner for Oil & Gas Projects

It is very important to choose the right partner for 6600V motors in oil and gas projects. This choice can have a big impact on the success and safety of your work. Before you look for a Chinese seller, here are some important things to keep in mind:

Manufacturing Capabilities and Quality Assurance

Check out the maker's plant and how they make sure the quality of their products. Look for businesses that have bought new tools for production and have strict programs in place to make sure the quality of their work. At the very least, the business needs to be recognized by ISO 9001. More industry-specific certifications can show that it cares more about quality.

Customization and Engineering Support

Motors for oil and gas often need to be made to order to meet specific needs. A good partner should let you make changes and have a team of skilled engineers who can help you figure out how to make the motor work best for you. To do this, you might need to change the cooling systems, use special coatings to keep them from rusting, or come up with your own designs for input boxes.

Supply Chain Reliability and Lead Times

Check to see how well the company can handle risks in the supply chain and stick to shipping dates. Find out how they keep track of their stock, how they get parts, and how long the lead times are for 6600V motors in general. You can avoid project delays and always have extra parts on hand if you have a good supply chain partner.

Conclusion

It is very cheap and of high quality to get 6600V motors from China if you need them for oil and gas work. To find reliable solutions that meet the strict service needs of the oil and gas industry, businesses can carefully screen manufacturers by looking at their credentials and experience in the field. They can then choose a partner with strong technical support and reliable supply lines. Being able to work with skilled Chinese manufacturers can give you the technological edge you need to make tough working conditions safer and more productive.

FAQ

1. What are the key safety features to look for in a 6600V motor for oil and gas applications?

Key safety features include explosion-proof enclosures, enhanced insulation systems rated for 6600V operation, comprehensive thermal protection mechanisms, and high ingress protection (IP) ratings. Additionally, look for motors certified to relevant standards such as ATEX or IECEx for use in hazardous environments.

2. How do Chinese manufacturers ensure the quality of 6600V motors for oil and gas projects?

Reputable Chinese manufacturers implement stringent quality control processes, including in-house testing facilities for routine and type tests as per IEC standards. They also maintain international certifications, invest in modern manufacturing equipment, and employ experienced engineering teams to ensure product quality and reliability.

3. What factors should be considered when selecting a Chinese supplier for 6600V motors in oil and gas applications?

Consider factors such as the manufacturer's certifications, field experience in oil and gas projects, technical capabilities, customization options, quality assurance processes, and supply chain reliability. Additionally, evaluate their engineering support, lead times, and ability to meet specific project requirements.

Power Up Your Oil & Gas Operations with XCMOTOR

There is no better partner than XCMOTOR when it comes to solid 6600V motors for tough oil and gas jobs. Because we've designed and built a lot of high-voltage motors for dangerous environments, you can be sure that the goods you get will meet the highest safety and performance standards. With our cutting-edge facilities and focused engineering team, we can make solutions that are perfect for your business. Choose XCMOTOR for 6600V motors that are the most reliable in the harshest situations. Don't skimp on quality or safety. Are you ready to step up your oil and gas business? Contact our expert team today at xcmotors@163.com and discover why XCMOTOR is the preferred 6600v motor supplier for industry leaders worldwide.

References

1. International Electrotechnical Commission. (2020). IEC 60079: Explosive atmospheres - Part 0: Equipment - General requirements.

2. American Petroleum Institute. (2021). API Standard 541: Form-wound Squirrel Cage Induction Motors - 500 Horsepower and Larger.

3. Zhang, L., et al. (2019). "Design and Analysis of High-Voltage Motors for Hazardous Environments in Oil and Gas Applications." IEEE Transactions on Industry Applications, 55(4), 3823-3831.

4. Wang, X. (2022). "Advancements in Explosion-Proof Motor Technologies for the Energy Sector." Journal of Electrical Engineering, 67(3), 145-152.

5. International Energy Agency. (2023). World Energy Outlook 2023.

6. Liu, J., et al. (2021). "Thermal Management Strategies for High-Voltage Motors in Extreme Environments." Applied Thermal Engineering, 188, 116627.

7. Chen, H. (2020). "China's Role in the Global Supply Chain of Industrial Electrical Equipment." Asian Journal of Technology Innovation, 28(2), 256-273.