The cement industry relies on powerful and dependable electric motors to carry out its energy-intensive activities. The whole cement-making machinery, from rotary kilns to raw material crushers, is powered by a 6600v motor. If you're in an extreme situation that requires constant operation with low power consumption and sturdy construction, these high-voltage motors are what you need. Machines used to make cement must be able to run nonstop in the face of high heat, dust, and mechanical stress.

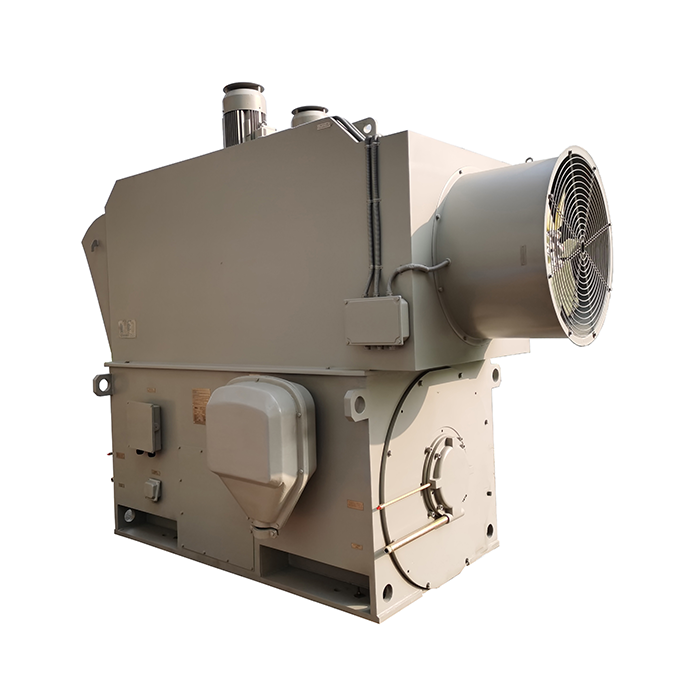

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Voltage Motors in Cement Manufacturing

Cement generation requires considerable electrical control to change crude limestone, clay, and other materials into the building blocks of advanced development. Tall voltage electric engines, especially those working at 6600V, give the vital torque and unwavering quality for heavy-duty mechanical applications. These engines ordinarily extend from 200kW to 6300kW, making them perfect for large-scale cement operations.

The cement fabrication handle includes numerous stages, each requiring specialized gear fueled by strong engines. From quarrying crude materials to bundling the last item, each step depends on dependable engine execution. The unforgiving conditions in cement plants, including high temperatures, rough cleaning, and nonstop operation cycles, require engines with predominant cover and assurance ratings.

Modern cement offices prioritize vitality utilization decrease while keeping up production productivity. Variable recurrence drives combined with tall voltage engines empower exact speed control, optimizing vitality utilization over diverse generation stages. This combination essentially decreases operational costs while amplifying gear lifespan.

Core Applications of 6600V Motors in Cement Plants

Raw Material Crushers and Grinding Mills

Raw fabric planning speaks to one of the most requested applications for tall voltage engines in cement plants. Essential crushers break down enormous limestone pieces, requiring engines with extraordinary beginning torque and stack capacity. These crushers ordinarily utilize synchronous or nonconcurrent engines rated between 1000kW to 3000kW.

Ball plants and vertical roller plants for crude fabric pounding expend gigantic amounts of energy. The pounding handle requires steady engine execution to keep up item quality and throughput. Engines driving these plants must handle variable loads as fabric characteristics alter through operation. Progressed engine control frameworks optimize pounding productivity while lessening vitality utilization by up to 20%.

Fans and Ventilation Systems

Cement plants require broad ventilation and discuss taking care of frameworks for tidy control, cooling, and handling optimization. Huge centrifugal fans fueled by tall voltage engines move gigantic volumes of discuss all through the office. These fans work ceaselessly, making unwavering quality and vitality productivity vital factors.

Kiln debilitates fans' handling of hot, dust-laden gases, requiring engines with strong development and specialized cooling. Cooling tower fans keep up ideal temperatures for different handling gear. The coordination of different fan frameworks makes legitimate wind current designs basic for secure and productive plant operation.

Conveyor and Material Handling Systems

Extensive conveyor networks transport materials throughout cement plants, from raw material storage to final product packaging. Belt conveyors require 6600v motors capable of handling varying loads and providing smooth acceleration to prevent material spillage.

Bucket elevators and pneumatic conveying systems use specialized motors designed for intermittent duty cycles. These applications demand motors with excellent starting characteristics and the ability to handle frequent direction changes. Motor protection systems prevent damage from material blockages and overload conditions.

Water Pumps and Cooling Systems

Cement plants expend critical water amounts for cooling, tidy concealment, and gear upkeep. High-pressure pumps fueled by dependable engines keep up a reliable water supply through the office. These pumps regularly work in inaccessible areas where support access is limited.

Cooling water circulation frameworks require nonstop operation to avoid gear overheating. Pump engines must give reliable stream rates while adjusting to changing framework weights. Energy-efficient engine plans decrease operational costs in these high-usage applications.

Compressors and Pneumatic Systems

Compressed discuss frameworks all through cement plants control pneumatic apparatuses, actuators, and cleaning gear. Expansive revolving compressors require engines with amazing beginning torque and load-handling capabilities. These frameworks frequently work discontinuously based on plant demand.

Pneumatic passing on frameworks for cement and added substances require exact weight control accomplished through variable speed engine drives. The mechanization of these frameworks decreases manual labor while improving fabric handling proficiency and lessening waste.

Benefits of High Voltage Motors in Cement Applications

High-voltage engines offer various focal points over lower voltage choices in cement plant applications. Control proficiency moves forward altogether at higher voltages, diminishing vitality losses in long cable runs common in huge cement offices. The diminished current at higher voltages permits smaller cable sizes, lessening installation costs.

Reliability becomes fundamental in cement plants where generation intrusions fetch thousands of dollars per hour. Tall voltage engines regularly include strong development with predominant cover and cooling frameworks. These engines handle requesting obligation cycles while keeping up steady execution over amplified periods.

Maintenance intervals extend considerably with high-voltage motors due to their robust design and lower operating currents. The reduced electrical stress on 6600v motor components translates to longer bearing life, improved insulation longevity, and fewer unexpected failures. Predictive maintenance programs become more effective with stable motor operation characteristics.

Energy consumption represents a significant operational expense in cement production. Modern high-voltage motors achieve efficiency ratings exceeding 95%, substantially reducing electrical costs. When combined with variable frequency drives, these motors provide additional energy savings through optimized speed control.

Technical Specifications and Performance Characteristics

Cement industry motors must meet stringent technical requirements to survive harsh operating conditions. Protection ratings of IP54 or higher protect against dust ingress while maintaining adequate ventilation for cooling. Insulation class F or H ensures reliable operation in high-temperature environments.

Speed ranges typically span 500-3000 RPM, allowing motor selection optimization for specific applications. Synchronous motors provide excellent power factor correction, reducing facility electrical demand charges. Asynchronous motors offer simpler maintenance and lower initial costs for many applications.

Motor design features include cast iron frames for durability, precision-machined components for smooth operation, and copper rotor bars for maximum conductivity. Bearing systems utilize premium brands like SKF, NSK, or FAG to ensure long service life under heavy loads. Advanced cooling systems maintain optimal operating temperatures even in demanding environments.

Installation and Maintenance Considerations

Proper establishment of tall voltage engines in cement plants requires cautious planning and execution. The establishment plan must oblige engine vibration and warm extension while giving satisfactory access for maintenance. Cable steering requires security from mechanical harm and natural hazards.

Maintenance programs ought to incorporate normal vibration checking, thermal imaging, and oil examination for bearing frameworks. Engine control center assessments guarantee legitimate electrical associations and assurance framework functionality. Prescient upkeep strategies recognize potential issues some advance, and recently they cause production interruptions.

Training programs for upkeep faculty ended up fundamental given the complexity of cutting-edge engine frameworks. Understanding engine control innovation, assurance frameworks, and demonstrative strategies guarantees ideal engine execution and life span. Customary preparing upgrades keep the work workforce current with advancing innovation and best practices.

Future Trends and Technology Developments

The cement industry is advancing toward expanded mechanization and digitalization. Savvy engine frameworks with coordinate sensors give real-time execution information for predictive upkeep and optimization. Web of Things (IoT) network empowers further checking and demonstrative capabilities.

Permanent magnet engines offer potential productivity enhancements for particular cement applications. Whereas higher beginning costs constrain broad selection, vitality reserve funds may legitimize speculation in basic applications. Proceeded improvement of attractive materials and fabrication forms may extend future applications.

Digitalization patterns incorporate progressed engine control algorithms that optimize execution based on real-time control conditions. Machine learning applications analyze operational information to foresee upkeep needs and optimize energy utilization. These advances guarantee advanced enhancements in engine reliability and efficiency.

Conclusion

High-voltage motors play an indispensable role in cement production, powering critical equipment from raw material crushers to finish mills. The demanding nature of cement manufacturing requires motors with exceptional reliability, energy efficiency, and robust construction. Modern 6600V motors deliver the performance characteristics necessary for successful cement operations while supporting industry sustainability goals through improved energy efficiency. Proper selection, installation, and maintenance of these motors directly impact production costs, equipment reliability, and environmental performance. As the cement industry continues advancing toward increased automation and digitalization, motor technology evolves to meet these changing requirements while maintaining the fundamental characteristics of reliability and efficiency that cement producers depend upon.

Frequently Asked Questions

Q1: What protection rating do cement plant motors require?

A: Cement plant motors typically require IP54 or IP55 protection to guard against dust ingress while maintaining adequate cooling. The harsh, dusty environment demands robust enclosures that prevent contamination while allowing proper ventilation.

Q2: How do variable frequency drives benefit cement motor applications?

A: Variable frequency drives provide precise speed control, reducing energy consumption by 15-30% in many applications. They enable soft starting, reduce mechanical stress, and allow process optimization through adjustable motor speeds matching production requirements.

Q3: What maintenance practices extend motor life in cement plants?

A: Regular vibration monitoring, thermal imaging, bearing lubrication, and electrical testing significantly extend motor life. Predictive maintenance programs identify issues before failures occur, while proper cleaning prevents dust accumulation and overheating.

Partner with XCMOTOR for Your Cement Industry Motor Solutions

In order to meet the rigorous demands of cement manufacturing, XCMOTOR has developed a whole suite of motor solutions tailored to industrial use. The dependability, efficiency, and performance that your cement operations need are delivered by our 6600v motor series. We provide motors designed to tackle the most demanding tasks in the cement industry, with power ratings ranging from 200 kW to 6300 kW.

We guarantee outstanding performance as a reliable 6600v motor manufacturer by combining cutting-edge production processes with stringent quality control. The precision-machined parts, long-lasting cast-iron structure, and high-quality SKF, NSK, and FAG bearings in our motors provide years of reliable operation. Reliability in the harsh cement plant environment is guaranteed by state-of-the-art cooling systems and exceptional insulation.

Our commitment to customer satisfaction includes fast delivery, 30-day returns, and dedicated support available every day of the week. When you choose XCMOTOR, you gain a partner dedicated to optimizing your cement production efficiency and reducing operational costs. Contact us at xcmotors@163.com to discuss your specific motor requirements and discover how our solutions can enhance your cement production operations.

References

1. IEEE Standard 841-2001: IEEE Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

2. Worrell, E., Kessels, A., Galitsky, C. "Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making." Lawrence Berkeley National Laboratory Report, 2008

3. Madlool, N.A., Saidur, R., Hossain, M.S., Rahim, N.A. "A Critical Review on Energy Use and Savings in the Cement Industries." Renewable and Sustainable Energy Reviews, Volume 15, 2011

4. International Electrotechnical Commission. "IEC 60034 Series: Rotating Electrical Machines Standards for Industrial Motor Applications"

5. Hasanbeigi, A., Price, L., Lin, E. "Emerging Energy-Efficiency and CO2 Emission-Reduction Technologies for Cement and Concrete Production." Ernest Orlando Lawrence Berkeley National Laboratory, 2012

6. National Electrical Manufacturers Association. "NEMA MG 1-2016: Motors and Generators Standard for High Voltage Industrial Applications"