The supply chain landscape for 4160 Volt Motor systems is undergoing a significant transformation as we enter 2026. Industrial automation sectors, including manufacturing facilities in automotive, aerospace, electronics, and food processing, face mounting pressure to streamline procurement processes. HVAC and refrigeration systems, energy utilities, and transportation industries are demanding faster delivery times while maintaining quality standards. This shift requires strategic supply chain optimization that addresses material shortages, manufacturing complexities, and logistics challenges that traditionally extend lead times for high-voltage motor systems.

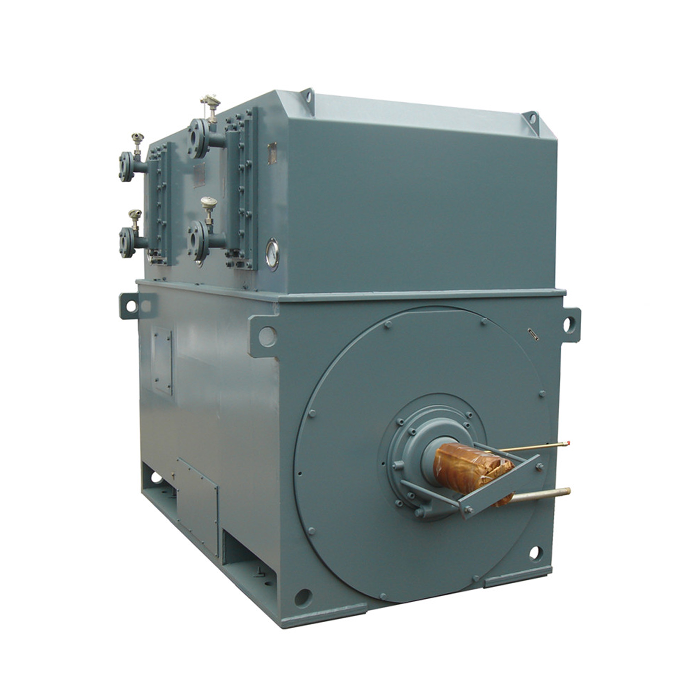

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Current Challenges in the 4160 Volt Motor Supply Chain

Supply chain disturbances have posed phenomenal challenges for mechanical engine obtainment. Fabricating offices across the United States report expanded holding up periods that straightforwardly affect production plans and extend timelines. The complexity of creating high-voltage engines requires specialized components and thorough testing conventions, which normally amplify fabrication cycles.

Material Shortages and Component Availability

Raw fabric shortage remains a basic bottleneck in engine fabricating. Copper estimating instability influences winding components, whereas steel deficiencies affect engine lodgings and basic components. Quality heading from producers gotten to be progressively troublesome to source, especially when clients require particular brands like SKF, NSK, or FAG heading for their applications. These fabric imperatives constrain producers to amplify generation plans and alter conveyance commitments.

Manufacturing Complexity and Quality Control

High-voltage engine generation includes perplexing fabrication forms that cannot be hurried without compromising quality. Engines working at 4160V, 6000V, or higher voltages require broad testing to guarantee separator efficiency and warm execution. Each unit experiences comprehensive quality affirmation conventions counting vibration testing, warm cycling, and electrical security confirmation. These fundamental strategies contribute to amplified lead times but guarantee long-term unwavering quality for basic mechanical applications.

Transportation and Logistics Bottlenecks

Global shipping disturbances proceed, influencing engine conveyance plans. Expansive mechanical engines require specialized transportation courses of action, counting custom crating and cargo coordination. Harbour clog and truck driver deficiencies compound these challenges, especially for overwhelming gear weighing a few tons. Residential fabricating capabilities offer assistance to relieve a few worldwide shipping delays, but the territorial transportation framework still faces capacity constraints.

Innovations and Strategies to Reduce Lead Times in 2026

Progressive producers are actualizing cutting-edge advances and vital organizations to quicken conveyance timelines. Advanced change activities empower real-time perceivability all through the supply chain, permitting buyers to track production progress and expect potential delays. Progressed fabrication procedures streamline generation while keeping up quality standards.

Digital Supply Chain Management

Real-time following frameworks give exceptional visibility into engine manufacturing advances. Prescient analytics offer assistance in recognizing potential bottlenecks some time recently they affect conveyance plans. Cloud-based stages empower consistent communication between buyers and providers, encouraging proactive problem-solving when issues emerge. These computerized devices change conventional receptive supply chains into proactive frameworks that expect and address challenges.

Strategic Supplier Collaboration

Collaborative planning between 4160 Volt Motor manufacturers and component suppliers reduces uncertainty and improves delivery predictability. Shared forecasting enables suppliers to maintain appropriate inventory levels for critical components. Integrated planning systems align production schedules across multiple suppliers, reducing coordination delays that traditionally extend lead times. Long-term partnerships with reliable suppliers create stability in an otherwise volatile supply environment.

Flexible Manufacturing Approaches

Modular engine plans adjust customization necessities with standardized components, empowering quicker gathering and conveyance. Pre-engineered engine stages suit different voltage prerequisites whereas keeping up common base plans. This approach permits producers to start generation utilizing accessible components whereas sourcing specialized components for last get together. The procedure altogether diminishes by and large lead times without compromising execution specifications.

Comparing Supply Chain Approaches for Different Voltage Motors

Supply chain complexity varies significantly across different motor voltage classes. Understanding these differences helps procurement professionals develop appropriate sourcing strategies for their specific applications. Higher voltage motors generally require longer lead times due to specialized components and enhanced testing requirements.

High Voltage Motor Considerations

Motors working at 4160V and over require specialized cover frameworks and improved security highlights. Fabricating these units includes extra quality control steps and amplified testing methods. Component sourcing gets to be more challenging as less providers create high-voltage appraised parts. The assurance level IP54 standard includes another layer of complexity, requiring fixed walled in areas that ensure against tidy and dampness whereas keeping up operational efficiency.

Manufacturing and Testing Requirements

High-voltage engines experience broad testing conventions that expand generation timelines. Cover resistance testing, high-potential testing, and warm execution approval require specialized hardware and gifted professionals. These engines must comply with GB/T 1032 and GB/T 13957 benchmarks, including administrative compliance steps to the fabricating prepare. Quality confirmation conventions guarantee long benefit life and solid operation but require extra time venture amid production.

Procurement Tips for B2B Clients: Navigating 4160 Volt Motor Buying in 2026

Successful motor procurement requires strategic planning and supplier relationship management. Early engagement with manufacturers enables better lead time management and helps secure production slots during peak demand periods. Understanding market dynamics and pricing factors allows buyers to make informed decisions that balance cost considerations with delivery requirements.

Supplier Selection and Relationship Management

Choosing the right supplier involves evaluating multiple factors beyond initial pricing. Manufacturing capabilities, quality certifications, and technical support services significantly impact long-term project success. Suppliers with proven track records in delivering motors with power ranges from 220 kW to 6300 kW demonstrate the scale and expertise necessary for large industrial projects. Established manufacturers typically maintain better component sourcing relationships, enabling more predictable delivery schedules.

Market Pricing and Cost Management

Commodity price fluctuations directly impact motor pricing throughout 2026. Copper and steel prices influence manufacturing costs, while energy expenses affect production overhead. Labor costs and transportation expenses add additional variables to final pricing structures. Buyers who understand these market drivers can better negotiate contracts and budget appropriately for their motor procurement needs. Volume purchasing agreements often provide cost advantages while securing priority production scheduling.

XCMOTOR: Your Trusted Partner for High-Performance Motor Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. (XCMOTOR) specializes in delivering reliable power equipment solutions tailored to diverse industrial applications. Our comprehensive product portfolio includes high-performance 4160 Volt Motors designed for fans, water pumps, compressors, crushers, cutting machine tools, and transportation machinery across various industries.

Advanced Technical Specifications

Our motor systems support multiple voltage configurations including 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%, and 11000V±5%. These versatile solutions accommodate diverse industrial requirements while maintaining consistent performance standards. Power ranges from 220 kW to 6300 kW enable applications from moderate-duty processes to heavy industrial operations requiring substantial mechanical output.

The following technical advantages distinguish our motor solutions from conventional alternatives:

- Low noise and vibration operation: Advanced rotor balancing and precision manufacturing reduce operational disturbances, creating more comfortable working environments while extending equipment lifespan through reduced mechanical stress.

- Extended service life design: High-grade materials and robust construction methods ensure reliable operation under demanding conditions, minimizing maintenance requirements and reducing total cost of ownership over extended operational periods.

- Simplified installation and maintenance: User-friendly design features facilitate straightforward installation procedures while accessible service points enable efficient maintenance operations, reducing downtime and service costs.

These performance characteristics address common industrial challenges while providing measurable operational benefits that justify investment in premium motor solutions.

Quality Assurance and Manufacturing Excellence

Our fabrication forms join accuracy die-casting methods that guarantee dimensional precision and component consistency. Progressed winding innovation optimizes electrical execution whereas decreasing energy consumption. Comprehensive quality control measures all through generation ensure dependable execution and long-term stability. Each engine experiences thorough testing conventions counting execution approval, security confirmation, and natural resistance testing.

Conclusion

Supply chain optimization for 4160 Volt Motor systems requires strategic planning, supplier collaboration, and technology adoption. Understanding current market challenges enables better procurement decisions while innovative approaches help reduce traditional lead time constraints. Digital supply chain management, flexible manufacturing, and strategic partnerships create competitive advantages for buyers seeking reliable motor solutions. XCMOTOR's commitment to quality, timely delivery, and comprehensive support services positions us as an ideal partner for organizations requiring dependable motor solutions in 2026.

Frequently Asked Questions

Q1: What factors most significantly impact lead times for high-voltage motors?

A: Raw material availability, manufacturing complexity, and quality testing requirements primarily determine lead times. Specialized components for high-voltage applications require longer sourcing periods, while comprehensive testing protocols ensure safety and performance standards are met.

Q2: How can buyers ensure quality compliance when sourcing custom motors?

A: Select certified manufacturers who comply with relevant industry standards and clearly define technical specifications upfront. Request documentation of quality control procedures and testing protocols to verify compliance with GB/T 1032 and GB/T 13957 standards.

Q3: What advantages do domestic suppliers offer compared to international manufacturers?

A: Domestic suppliers typically provide faster response times, reduced shipping complexity, and easier communication for technical support. Local manufacturers also offer better flexibility for customization requests and faster resolution of any post-delivery issues that may arise.

Partner with XCMOTOR for Reliable Motor Solutions

Ready to optimize your motor procurement strategy and reduce lead times? XCMOTOR offers comprehensive consultation services designed to streamline your acquisition process while ensuring competitive pricing and reliable delivery schedules. Our experienced team provides personalized assessments of your specific requirements, helping you select the ideal 4160 Volt Motor manufacturer solution for your industrial applications. We welcome inquiries about customization options, bulk order pricing, and technical specifications that meet your operational needs. Contact us at xcmotors@163.com to discuss your motor requirements and discover how our expertise can enhance your project success.

References

1. Industrial Motor Supply Chain Analysis: Global Trends and Regional Impacts, Manufacturing Engineering Journal, 2024.

2. High-Voltage Motor Manufacturing: Quality Control and Lead Time Optimization Strategies, IEEE Electrical Systems Review, 2025.

3. Supply Chain Resilience in Industrial Equipment Procurement, B2B Manufacturing Today, 2024.

4. Digital Transformation in Motor Manufacturing: Technology Adoption and Performance Metrics, Industrial Automation Quarterly, 2025.

5. Market Analysis of High-Voltage Motor Systems: Demand Forecasting and Supply Chain Challenges, Electrical Equipment Industry Report, 2024.

6. Procurement Best Practices for Industrial Motor Systems: Cost Management and Supplier Selection, Manufacturing Procurement Review, 2025.