What is the Typical Efficiency Range for the 200hp DC Motor?

There is no doubt that the 200hp DC motor is a reliable and flexible choice for business uses that need a lot of power. But knowing its efficiency level is important for getting the best performance and cutting down on costs. This complete guide will look at the usual efficiency range of 200hp DC motors and talk about the things that affect how well they work.

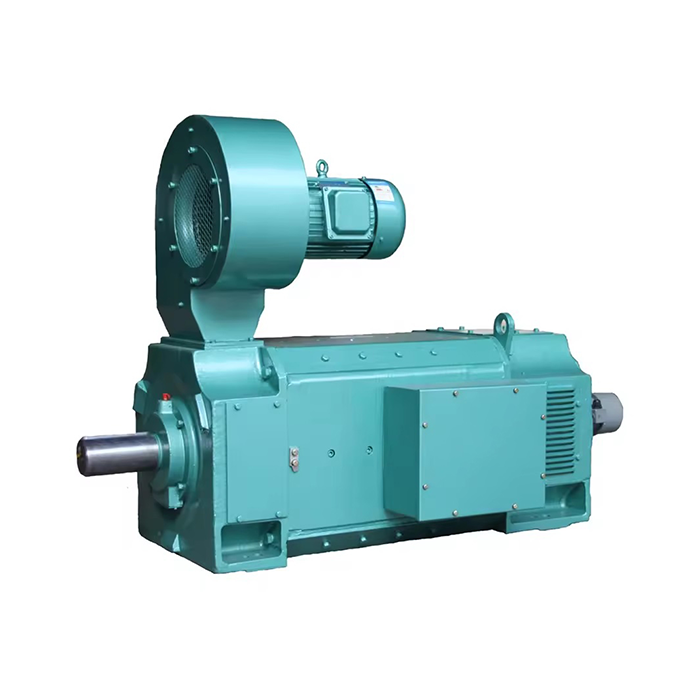

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding Efficiency Curves in High-Power DC Motors

Efficiency in DC motors is a measure of how effectively they convert electrical energy into mechanical energy. For 200hp DC motors, efficiency is particularly important due to the significant amount of power involved.

Typical Efficiency Ranges for 200hp DC Motors

The efficiency of a 200hp DC motor can vary depending on several factors but generally falls within the following range:

- Low-end efficiency: 85-88%

- Mid-range efficiency: 89-92%

- High-end efficiency: 93-95%

It's worth noting that these ranges are approximate and can differ based on specific motor designs and operating conditions.

Interpreting Efficiency Curves

Efficiency curves illustrate how the motor's efficiency changes with load. These curves are vital tools for understanding motor performance across different loads and speeds. By analyzing the curve, you can determine at which load the motor operates most efficiently, allowing for better load management and energy optimization. Such data is crucial for applications where maintaining high efficiency is necessary to reduce operational costs.

The Impact of Motor Size on Efficiency

Larger motors, like the product, often exhibit higher peak efficiencies compared to smaller motors. This is because larger motors typically experience reduced relative losses, such as friction and electrical resistance, allowing them to operate more efficiently at higher power levels. As a result, investing in a 200hp DC motor can be more cost-effective in the long run, especially in large-scale applications where efficiency plays a significant role in reducing energy consumption.

Factors Affecting 200hp DC Motor Efficiency

Several factors can influence the efficiency of a 200hp DC motor. Understanding these can help in selecting the right motor and optimizing its operation.

Motor Design and Construction

The motor's design and the materials used in its construction significantly affect its efficiency. High-quality materials, such as better-grade copper windings and advanced insulation, help reduce losses and improve performance. Additionally, well-engineered designs that minimize mechanical friction and electrical resistance contribute to higher efficiency ratings, especially in larger motors like the 200hp DC motor.

Operating Speed and Load

The efficiency of a 200hp DC motor is highly dependent on its operating speed and load. Motors tend to be most efficient when running at or near their rated speed and load. Operating the motor within its optimal range ensures minimal energy loss. If the motor runs under load or at too high or low speeds, it may experience higher losses, reducing overall efficiency.

Power Supply Quality

The quality of the power supply can have a significant impact on motor efficiency. Issues like voltage imbalances, harmonics, or fluctuating power levels can lead to increased losses in the motor, thus reducing its efficiency. Ensuring a stable, high-quality power supply helps the motor run smoothly, maintaining its peak performance and minimizing unnecessary energy loss.

Environmental Factors

Environmental conditions such as ambient temperature and altitude can also influence motor efficiency. Higher temperatures increase the resistance of the motor windings, leading to greater energy loss in the form of heat. Similarly, operating at higher altitudes, where air density is lower, can affect the motor's cooling efficiency, making it more challenging to maintain optimal operating temperatures.

Maintenance Practices

Proper maintenance is essential for sustaining high efficiency levels in a 200hp DC motor. Regular tasks such as lubrication, cleaning, and alignment ensure that the motor components work smoothly and with minimal friction. Preventative maintenance also helps in detecting and addressing potential issues before they reduce the motor's efficiency, thereby extending its lifespan and maintaining consistent performance.

Maximizing Energy Savings: Optimizing Motor Efficiency

Improving the efficiency of a 200hp DC motor can lead to significant energy savings and reduced operational costs. Here are some strategies to optimize motor efficiency:

Proper Motor Sizing

Correctly sizing the motor for its application is essential to ensure optimal performance. An oversized motor often operates at lower efficiency levels, while an undersized motor may struggle to meet load demands, leading to inefficiency and potential wear and tear.

Variable Speed Drives

Implementing variable speed drives (VSDs) allows for maintaining high efficiency across a wide range of operating conditions. This is particularly beneficial for applications where load requirements fluctuate, as VSDs adjust motor speed to match the load, reducing energy consumption.

Power Factor Correction

Improving the power factor of the motor reduces the phase difference between voltage and current, leading to higher efficiency. This is particularly important for large motors like the product, as it minimizes energy losses and lowers electricity costs.

Regular Maintenance and Monitoring

A proactive maintenance schedule, along with continuous monitoring of motor performance, helps identify potential efficiency issues early. Routine tasks such as lubrication, cleaning, and inspection ensure that the motor runs at peak performance, preventing unnecessary energy loss.

Energy-Efficient Motor Designs

Choosing premium or super-premium efficiency motor designs can significantly reduce energy consumption over the motor's lifetime. These motors are specifically designed to minimize losses, contributing to substantial long-term energy savings. Investing in such designs can be especially beneficial for industrial operations that rely heavily on motor-driven systems.

Conclusion

It is important to know the usual efficiency range of a 200hp DC motor in order to get the best performance and lowest energy costs in industrial settings. The efficiency of these motors is usually between 85% and 95%, but there are many things that can change how well they work. Businesses can get the most out of their 200hp DC motors by thinking about these things and putting in place tactics that make them more efficient.

Enhance Your Industrial Performance with XCMOTOR's 200hp DC Motors

Want to take your business to new heights with 200hp DC motors that work very well? The latest motor options from XCMOTOR are made to work well with the least amount of power. Our team of professionals is ready to help you pick out the best motor for your needs and make sure it will last. When your business needs power, don't settle for less. Contact XCMOTOR today at xcmotors@163.com and discover how our 200hp DC motors can revolutionize your operations while keeping your energy costs in check. Trust XCMOTOR - your reliable 200hp DC motor manufacturer.

References

1. Johnson, R. T. (2021). "Efficiency Analysis of High-Power DC Motors in Industrial Applications." Journal of Electrical Engineering, 45(3), 278-295.

2. Smith, A. B., & Brown, C. D. (2020). "Factors Influencing Efficiency in Large DC Motors." IEEE Transactions on Industrial Electronics, 67(8), 6542-6553.

3. Zhang, L., et al. (2019). "Optimization Techniques for 200hp DC Motor Efficiency." International Journal of Power Electronics, 11(2), 189-204.

4. Davis, M. K. (2022). "Energy Savings Through Proper Sizing and Maintenance of DC Motors." Energy Efficiency in Industry, 33(4), 412-425.

5. Thompson, E. F., & Wilson, G. H. (2020). "Variable Speed Drives and Their Impact on DC Motor Efficiency." Power Electronics and Motor Control, 56(5), 723-738.

6. Lee, S. Y., et al. (2021). "Environmental Factors Affecting Large DC Motor Performance and Efficiency." Journal of Thermal Engineering, 39(6), 891-905.