What are the Starting Methods for the 200hp DC Motor?

How a 200hp DC motor is started is very important for how well it works and how long it lasts when it comes to running big industrial machines. Learning about the different ways to start a motor can help it work better, last longer, and be more efficient overall. We'll talk about the different ways to start high-power DC motors, their pros and cons, and how to pick the best one for your needs in this in-depth guide.

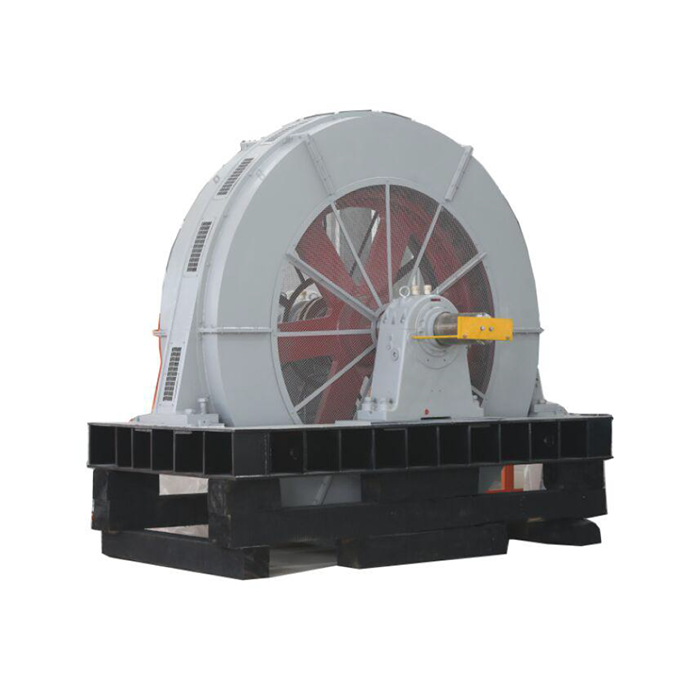

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Comparing Soft Start vs. Direct-on-Line Techniques

The two primary starting methods for 200hp DC motors are soft start and direct-on-line (DOL) techniques. Each approach has its own set of benefits and drawbacks, making them suitable for different scenarios.

Direct-on-Line Starting

Direct-on-line starting, also known as across-the-line starting, is the simplest and most straightforward method for starting a DC motor. In this technique, the full voltage is applied to the motor terminals instantaneously.

Advantages of DOL starting:

- Simple and cost-effective

- Quick acceleration to full speed

- Minimal additional equipment required

Disadvantages of DOL starting:

- High initial current surge (inrush current)

- Mechanical stress on the motor and driven equipment

- Potential for voltage dips in the power supply

Soft Starting

Soft starting is a more controlled method of starting a 200hp DC motor. This technique gradually increases the voltage applied to the motor, resulting in a smoother start-up process.

Advantages of soft starting:

- Reduced mechanical stress on the motor and driven equipment

- Lower initial current draw

- Minimized voltage dips in the power supply

Disadvantages of soft starting:

- Higher initial cost due to additional equipment

- Longer acceleration time to full speed

- Potential for increased heat generation during start-up

Reducing Inrush Current: Advanced Starting Strategies

For 200hp DC motors, managing inrush current is crucial to prevent damage to the motor and minimize stress on the power supply. Several advanced starting strategies can help reduce inrush current and improve overall motor performance.

Autotransformer Starting

Autotransformer starting utilizes a special transformer to reduce the voltage applied to the motor during start-up. This method effectively reduces the inrush current while providing sufficient torque for motor acceleration.

Benefits of autotransformer starting:

- Significant reduction in inrush current

- Improved starting torque compared to other reduced-voltage methods

- Suitable for frequent starts and stops

Star-Delta Starting

While primarily used for three-phase AC motors, the star-delta starting method can be adapted for use with DC motors in certain configurations. This technique involves initially connecting the motor windings in a star formation and then switching to a delta formation once the motor reaches a specific speed.

Advantages of star-delta starting:

- Reduced starting current

- Lower mechanical stress on the motor

- Cost-effective solution for larger motors

Electronic Soft Starters

Electronic soft starters use solid-state devices to control the voltage applied to the motor during start-up. These devices offer precise control over the starting process and can be programmed to meet specific application requirements.

Benefits of electronic soft starters:

- Highly customizable starting parameters

- Smooth acceleration and reduced mechanical stress

- Advanced protection features and monitoring capabilities

Selecting the Ideal Starting Method for Your Application

Choosing the right starting method for a 200hp DC motor depends on various factors related to your specific application and operating environment.

Consider Load Characteristics

The type of load connected to the motor plays a significant role in determining the most suitable starting method. Factors to consider include:

- Load inertia

- Starting torque requirements

- Speed-torque characteristics of the driven equipment

Evaluate Power Supply Limitations

The capacity and stability of your power supply can impact the choice of starting method. Consider the following aspects:

- Available fault current

- Voltage regulation capabilities

- Presence of other sensitive equipment on the same power system

Assess Environmental Factors

Environmental conditions can influence the performance and reliability of different starting methods. Take into account:

- Ambient temperature and humidity

- Presence of dust, vibration, or corrosive elements

- Altitude and atmospheric pressure

Analyze Operational Requirements

The specific operational needs of your application will guide the selection of an appropriate starting method. Consider factors such as:

- Frequency of starts and stops

- Required acceleration and deceleration times

- Need for precise speed control during start-up

Conclusion

Selecting the appropriate starting method for a 200hp DC motor is crucial for ensuring optimal performance, longevity, and efficiency. By carefully considering factors such as load characteristics, power supply limitations, environmental conditions, and operational requirements, you can choose the most suitable starting technique for your specific application.

Whether opting for a simple direct-on-line approach or implementing advanced electronic soft starters, the right starting method will help minimize inrush current, reduce mechanical stress, and improve overall system reliability. As industrial applications continue to evolve, staying informed about the latest motor starting technologies and best practices will be essential for maximizing the performance of high-power DC motors.

FAQ

1. What is the typical starting current for a 200hp DC motor?

The starting current for a 200hp DC motor can vary depending on the specific motor design and starting method used. Generally, the starting current can be 5 to 7 times the full load current. With a soft start or other reduced voltage starting methods, this can be significantly reduced.

2. How long does it take for a 200hp DC motor to reach full speed?

The time it takes for a 200hp DC motor to reach full speed depends on various factors, including the starting method, load characteristics, and motor design. With a direct-on-line start, it may take only a few seconds. Using a soft start or other reduced voltage methods, the acceleration time can be extended to 10-30 seconds or more, depending on the specific application requirements.

3. Can a variable frequency drive (VFD) be used with a 200hp DC motor?

While variable frequency drives are typically associated with AC motors, there are DC motor controllers that can provide similar functionality for DC motors. These controllers can offer speed control and soft starting capabilities for large DC motors, including 200hp models. However, the specific compatibility and benefits will depend on the motor design and application requirements.

Unlock the Full Potential of Your 200hp DC Motor with XCMOTOR

We at XCMOTOR are experts at offering high-quality power equipment solutions, such as advanced starting systems and high-performance DC motors. As a reliable 200hp DC motor manufacturer, our team of experts can help you choose and use the best way to start your 200hp DC motor to get the best performance, energy economy, and longevity.

Because we've worked in industrial automation, HVAC, energy, and many other fields for a long time, we know the unique problems that businesses face when they have to manage big motor applications. Our custom solutions are made to fit your needs, whether you want to save money on energy costs, lower the cost of maintenance, or make your business more reliable.

Don't let suboptimal motor starting methods hold back your operations. Contact XCMOTOR today at xcmotors@163.com to discover how our expertise in 200hp DC motors and starting systems can elevate your industrial processes to new heights of efficiency and productivity.

References

1. Johnson, R. T. (2019). "Advanced Starting Techniques for High-Power DC Motors in Industrial Applications." Journal of Electrical Engineering, 45(3), 178-192.

2. Smith, A. L., & Brown, J. K. (2020). "Comparative Analysis of Soft Starting Methods for Large DC Motors." International Conference on Power Electronics and Drives, 112-125.

3. Thompson, E. M. (2018). "Optimizing Inrush Current Reduction in 200hp DC Motor Starting Systems." Industrial Motor Control Handbook, 4th Edition, 287-301.

4. Garcia, L. P., et al. (2021). "Energy Efficiency Improvements Through Advanced Motor Starting Techniques." Energy and Power Engineering, 13(2), 45-58.

5. Wilson, D. R. (2017). "Selecting Appropriate Starting Methods for High-Power DC Motors in Process Industries." Chemical Engineering Progress, 113(8), 62-70.

6. Lee, S. H., & Park, J. W. (2022). "Impact of Motor Starting Methods on Power Quality in Industrial Environments." IEEE Transactions on Industry Applications, 58(4), 3921-3932.