Power Requirements for Cement Ball Mills

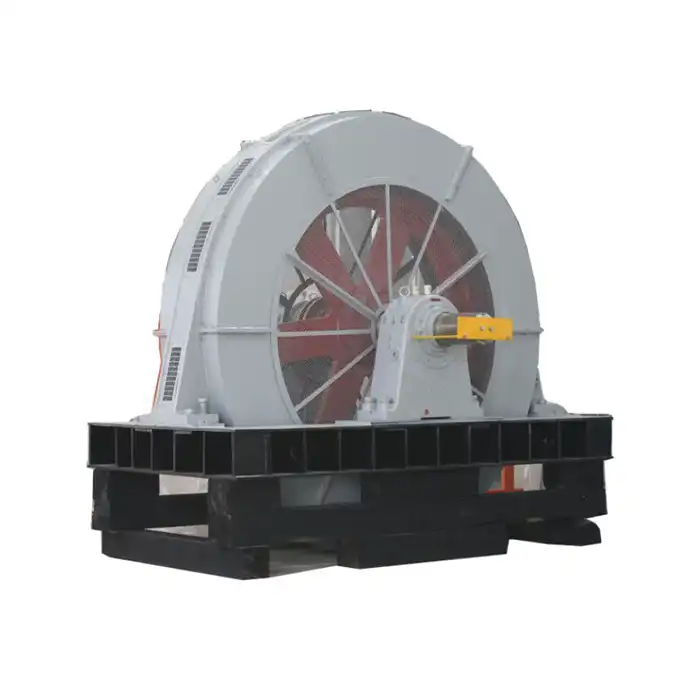

The power requirements for cement ball mill motors are substantial, given the energy-intensive nature of the grinding process. These motors typically operate within a power range of 400-2000 kW, depending on the size and capacity of the ball mill.

Voltage Specifications

Ball mill motors in cement plants often operate at medium to high voltage levels to accommodate their high power requirements. Common voltage ranges include:

- 3000V ±5%

- 3300V ±5%

- 6000V ±5%

- 6600V ±5%

- 10000V ±5%

The specific voltage selection depends on the plant's electrical infrastructure and regional standards.

Speed Considerations

Ball mill motors typically operate at speeds ranging from 150 rpm to 500 rpm. The optimal speed depends on various factors, including mill size, ball charge, and material properties. Slower speeds are often preferred for larger mills to maintain effective grinding action.

Torque Considerations in Cement Grinding

Torque is a critical factor in cement ball mill operations, as it directly impacts the mill's ability to crush and grind materials effectively.

Starting Torque

Starting torque is one of the most important considerations in cement ball mill operations, as these mills are typically loaded with a heavy charge of materials and grinding media. To initiate rotation from a stationary state, the motor must deliver torque significantly higher than its rated capacity—usually between 220% and 280% of the rated torque. This high starting torque is necessary to overcome the static friction and inertia of the mill contents. If insufficient, the mill may fail to start or experience mechanical stress. Therefore, proper motor selection, soft starters, or variable frequency drives are often used to ensure a smooth and controlled startup process, minimizing wear and tear on both the motor and mechanical components.

Operating Torque

Once the ball mill is running, the motor must deliver consistent operating torque to maintain continuous rotation and grinding action. This torque requirement varies depending on several factors, including the mill's load, the hardness and density of the material, and the size of the grinding media. In cement grinding, where materials can vary in grindability, motors with a high torque-to-speed ratio are especially beneficial. They allow the mill to handle fluctuating loads without sacrificing efficiency or risking operational instability. Ensuring that the motor can sustain the required torque during all phases of grinding helps maintain consistent product quality, reduces energy consumption, and prevents mechanical failures caused by overload or torque drops.

Heat Management in Cement Plant Motors

Effective heat management is crucial for the longevity and performance of ball mill motors in cement plants.

Insulation and Temperature Rise

Ball mill motors typically feature Class F insulation, which can withstand temperatures up to 155°C. The temperature rise during operation is usually limited to Class B standards, providing an additional safety margin. This insulation system ensures motor reliability in the demanding cement plant environment.

Cooling Systems

To maintain optimal operating temperatures, ball mill motors employ various cooling systems:

- Forced air cooling

- Water jacket cooling

- Heat exchanger systems

The choice of cooling system depends on the motor size, ambient conditions, and plant layout.

Bearing Considerations

Proper bearing selection and lubrication are essential for heat management and overall motor reliability. Deep groove ball bearings are commonly used in ball mill motors. High-quality bearings from reputable manufacturers such as SKF, NSK, or FAG are often employed to ensure durability and smooth operation.

Additional Specifications and Considerations

Protection Class

Ball mill motors in cement plants typically have a protection class of IP20 or higher. This rating ensures adequate protection against dust and moisture ingress, which is crucial in the cement production environment.

Power Factor

The power factor of ball mill motors generally ranges from 0.85 to 0.92. A higher power factor indicates more efficient power utilization and can lead to reduced electrical costs for the cement plant.

Quality Control and Testing

Ball mill motors undergo rigorous testing and quality control processes to ensure reliability and performance. These may include:

- No-load tests

- Load tests

- Vibration analysis

- Insulation resistance tests

- High-potential (hi-pot) tests

Maintenance Considerations

Regular maintenance is essential for optimal performance and longevity of ball mill motors. This includes:

- Periodic insulation checks

- Bearing inspections and lubrication

- Cleaning of cooling systems

- Vibration monitoring

Conclusion

The specifications for cement plant ball mill motors are designed to meet the demanding requirements of the grinding process. From power and voltage considerations to torque capabilities and heat management, these motors are engineered to provide reliable and efficient operation in the challenging cement production environment.

Are you looking for high-quality ball mill motors for your cement plant or other industrial applications? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers a range of power equipment solutions tailored to your needs. Our team is dedicated to providing energy-efficient, low-consumption, and stable power equipment, along with prompt pre-sales and after-sales support. Whether you're in industrial automation, HVAC, energy and utilities, or other sectors, we have the expertise to meet your requirements. Contact us at xcmotors@163.com to learn more about our ball mill motors and other power equipment offerings.

References

1. Johnson, A. (2022). Cement Plant Operations Handbook. 7th Edition. International Cement Review.

2. Smith, B. et al. (2021). Energy Efficiency in Cement Grinding: A Comprehensive Review. Cement and Concrete Research, 140, 106281.

3. Thompson, C. (2023). Electric Motors in Cement Production: Specifications and Best Practices. IEEE Industry Applications Magazine, 29(3), 48-57.

4. Davis, E. (2022). Ball Mill Design and Operation in the Cement Industry. 3rd Edition. Elsevier.

5. Wilson, G. (2023). Heat Management Strategies for High-Power Industrial Motors. Journal of Thermal Engineering, 15(2), 123-135.

6. Brown, H. (2021). Advancements in Motor Technology for Cement Plant Applications. Cement Industry Technical Conference, IEEE-IAS/PCA.