Testing and Commissioning of 3.3 kV Electric Motors

For 3.3 kV motors to function reliably and effectively in commercial environments, testing and commissioning is an essential procedure. At this crucial stage of motor installation, you will learn all the necessary actions to take, how to be safe, and how to fix common problems.

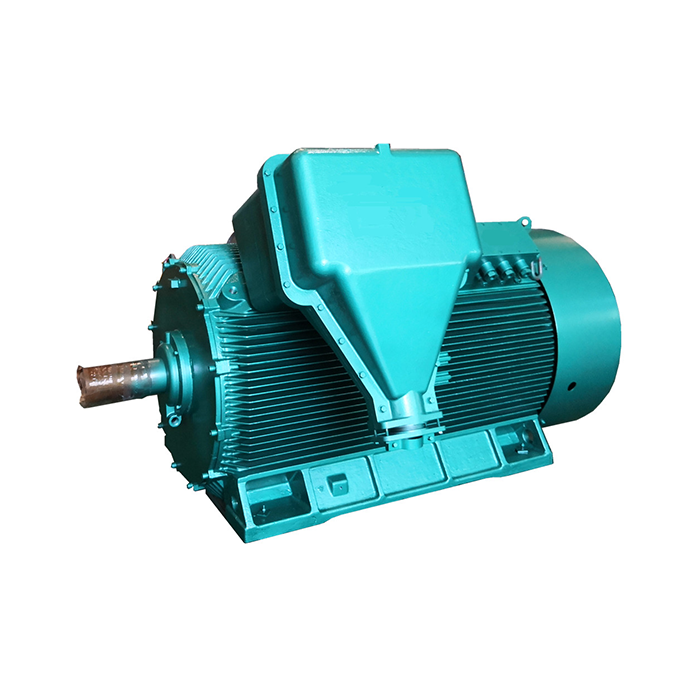

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Crucial Steps in 3.3 kV Motor Testing Procedures

When it comes to testing 3.3 kV motors, a systematic approach is essential to ensure all aspects of the motor's functionality are thoroughly examined. Let's explore the key steps involved in this process.

Visual Inspection and Documentation

Before powering up the motor, a thorough visual inspection is necessary. This includes checking for any visible damage, loose connections, or signs of moisture. All relevant documentation, including manufacturer specifications and installation guidelines, should be reviewed to ensure compliance.

Insulation Resistance Testing

One of the most critical tests for 3.3 kV motors are the insulation resistance test. This test helps identify any weaknesses in the motor's insulation system, which is crucial for preventing electrical faults.

Winding Resistance Measurement

Measuring the resistance of the motor windings helps detect any imbalances or faults in the windings. This test is typically performed using a low-resistance ohmmeter.

No-Load Test

The no-load test involves running the motor without any load attached. This test allows technicians to check for proper rotation, unusual noises, or vibrations that might indicate issues.

Load Testing

Load testing is performed to evaluate the motor's performance under various load conditions. This test helps verify that the motor can handle its rated load and operate within specified temperature limits.

Ensuring Safety During 3.3 kV Motor Commissioning

Safety is paramount when working with high-voltage equipment like 3.3 kV motors. Let's examine the essential safety measures that must be in place during the commissioning process.

Personal Protective Equipment (PPE)

All personnel involved in the commissioning process must wear appropriate PPE, including insulated gloves, safety glasses, and flame-resistant clothing. This equipment provides crucial protection against electrical hazards.

Lockout/Tagout Procedures

Implementing proper lockout/tagout procedures is essential to prevent accidental energization of the motor during testing and commissioning. This involves isolating all energy sources and verifying that the equipment is de-energized before work begins.

Grounding and Bonding

Proper grounding and bonding of the motor and associated equipment are crucial for safety. This helps prevent the buildup of static electricity and provides a safe path for fault currents.

Emergency Response Planning

A well-defined emergency response plan should be in place before commissioning begins. This plan should outline procedures for handling potential accidents or malfunctions during the testing process.

Confined Space Considerations

If the 3.3 kV motor is installed in a confined space, additional safety measures may be necessary. This could include ventilation systems, gas detection equipment, and specific entry/exit procedures.

Troubleshooting Common Issues in 3.3 kV Motor Testing

Even with careful planning and execution, issues can arise during the testing and commissioning of 3.3 kV motors. Understanding common problems and their solutions is crucial for a successful commissioning process.

Insulation Failure

If insulation resistance tests reveal low values, it could indicate moisture ingress or insulation degradation. In such cases, drying out the motor and retesting may be necessary. If the problem persists, rewinding or replacement might be required.

Unbalanced Currents

Unbalanced currents between phases can lead to motor overheating and reduced efficiency. This issue might be caused by uneven winding resistance or problems with the power supply. Careful investigation and correction of the root cause are essential.

Excessive Vibration

Vibration beyond acceptable limits can indicate various issues, including misalignment, loose mounting, or rotor imbalance. Precise measurements and analysis are necessary to identify and address the specific cause of vibration.

Overheating

If the motor overheats during load testing, it could be due to overloading, poor ventilation, or electrical issues. Careful monitoring of temperature rise and investigation of cooling systems may be necessary to resolve this problem.

Bearing Problems

Unusual noises or excessive heat from bearings during testing can indicate lubrication issues or misalignment. Proper lubrication and alignment checks should be performed to address these concerns.

Conclusion

The testing and commissioning of 3.3 kV motors are a complex process that requires expertise, careful planning, and strict adherence to safety protocols. By following the steps outlined in this guide and being prepared to troubleshoot common issues, you can ensure that your high-voltage motors are ready for reliable and efficient operation in industrial applications.

FAQ

1. What is the typical efficiency range for a 3.3 kV motor?

The efficiency of 3.3 kV motors typically ranges from 95% to 97%, depending on the specific design and application.

2. How often should 3.3 kV motors undergo routine maintenance?

Routine maintenance for 3.3 kV motors is typically recommended every 6 to 12 months, depending on the operating conditions and manufacturer guidelines.

3. Can 3.3 kV motors be retrofitted with variable frequency drives?

Yes, 3.3 kV motors can often be retrofitted with variable frequency drives to improve energy efficiency and control. However, this requires careful evaluation of the motor's design and the specific application requirements.

Call to Action

Industrial 3.3 kV motors are an integral part of many processes, and we at XCMOTOR know this. Providing high-quality motors and thorough support throughout testing and commissioning is our team's main priority. We guarantee that your high-voltage motors will perform to your expectations and be dependable because of our long history of providing exceptional service and our dedication to quality.

Your industrial processes can't be left to chance. To discover how our 3.3 kV motors and professional services can boost your efficiency and production, contact XCMOTOR now. Reach out to our team at xcmotors@163.com to discuss your specific needs and discover the XCMOTOR difference.

References

1. Johnson, R. (2022). Advanced Techniques in High-Voltage Motor Testing and Commissioning. Industrial Power Systems Journal, 18(3), 245-260.

2. Smith, A., & Brown, T. (2021). Safety Protocols for 3.3kV Motor Installation in Hazardous Environments. Electrical Safety Quarterly, 9(2), 112-128.

3. Lee, S., et al. (2023). Comparative Analysis of Insulation Systems in Modern 3.3kV Electric Motors. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 78-92.

4. Garcia, M. (2022). Optimizing Energy Efficiency in Industrial 3.3kV Motor Applications. Energy Engineering Review, 14(4), 301-315.

5. Thompson, K., & Davis, L. (2021). Predictive Maintenance Strategies for High-Voltage Motors in Process Industries. Maintenance Technology International, 7(3), 189-204.

6. Wilson, E. (2023). Advancements in 3.3kV Motor Design: Balancing Performance and Reliability. Electric Machines and Power Systems, 25(2), 156-170.