Speed Control Methods for 3.3kV Motors

In industrial settings, managing the speed of high-voltage motors is important for making processes run more smoothly, saving energy, and making equipment last longer. This article talks about different ways to control the speed of 3.3kV motors, which is a typical voltage rating for medium-voltage uses.

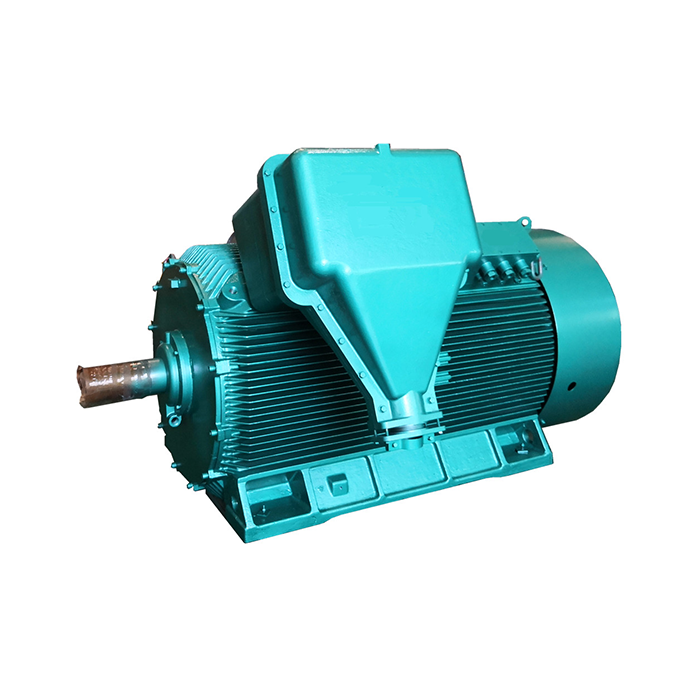

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Variable Frequency Drives: Precision at High Voltages

Variable Frequency Drives (VFDs) are among the most effective and versatile methods for controlling the speed of 3.3kV motors. These devices allow for precise speed regulation by adjusting the frequency and voltage supplied to the motor.

How VFDs Work with 3.3kV Motors

VFDs transform a 50Hz or 60Hz power supply into a variable-frequency output. This adaptation lets the motor run at varied speeds depending on the application. 3.3kV motors need medium-voltage VFDs to accommodate greater voltages. Variable frequency drives (VFDs) smooth motor running and protect it from voltage spikes and power supply fluctuations. VFDs improve industrial process control, energy efficiency, and mechanical component wear by precisely adjusting motor speed. They also optimize variable-load performance, making them essential in pumping and manufacturing.

Benefits of VFDs for 3.3kV Motor Control

1. Precise speed control across a wide range

2. Improved energy efficiency, especially at partial loads

3. Soft starting capabilities, reducing mechanical stress

4. Advanced protection features for motor and drive

Considerations When Implementing VFDs

While VFDs offer numerous advantages, there are some factors to consider:

1. Higher initial cost compared to simpler control methods

2. Potential for harmonic distortion in the power system

3. Need for proper cable shielding and grounding

4. Cooling requirements for drive components

Soft Starters vs. Direct-on-Line: Pros and Cons

When it comes to starting 3.3kV motors, soft starters and direct-on-line (DOL) methods are two common approaches. Each has its advantages and limitations, particularly when it comes to speed control.

Soft Starters for 3.3kV Motors

Soft starters reduce inrush current by gradually increasing voltage when starting the motor. This regulated startup reduces motor electrical and mechanical stress, extending its lifespan and reducing power surge damage. Soft starts are useful in locations with low electrical capacity or where a gentle motor start is needed to prevent equipment damage. Soft starts reduce gear and belt wear as the motor gradually reaches full speed, improving system reliability and lowering maintenance costs. Soft starters focus on motor starting, making them less useful for precise speed control. Since they are designed for single-start applications, they may not work for numerous start/stop cycles.

Advantages of Soft Starters:

- Reduced mechanical stress on the motor and driven equipment

- Lower starting current, minimizing voltage dips in the power system

- Some speed control capability during startup and shutdown

Limitations:

- Limited speed control once the motor reaches full speed

- May not be suitable for applications requiring frequent speed changes

Direct-on-Line Starting for 3.3kV Motors

DOL starting involves connecting the motor directly to the power supply, resulting in a rapid acceleration to full speed.

Advantages of DOL Starting:

- Simple and cost-effective

- Reliable for motors that don't require speed control

- High starting torque

Limitations:

- No speed control capabilities

- High inrush current and mechanical stress during startup

- Not suitable for applications requiring gradual acceleration

Choosing Between Soft Starters and DOL

The choice between soft starters and DOL starting depends on the specific application requirements. For processes that need speed control or have sensitive equipment, soft starters or VFDs are generally preferred over DOL starting.

Advanced Control Techniques for Energy Efficiency

As energy efficiency becomes increasingly important, advanced control techniques for 3.3kV motors have been developed to optimize performance and reduce energy consumption.

Vector Control for Improved Efficiency

Vector control, also called field-oriented control (FOC), is a complex magnetic field-based motor speed and torque control system. Vector control controls the motor's flux and torque-producing components independently, unlike voltage or frequency control. This precision in control optimizes motor efficiency, generating greater power with less energy. Vector control excels in pumps, fans, and conveyors that need speed and torque precision. This sophisticated method reduces energy expenses and mechanical component wear, enhancing system efficiency and motor and equipment longevity.

Benefits of Vector Control:

- High dynamic performance, even at low speeds

- Improved efficiency across the speed range

- Better torque control, especially at low speeds

Power Factor Correction

Improving the power factor of 3.3kV motors can lead to significant energy savings and reduced electrical system losses.

Methods for Power Factor Correction:

- Capacitor banks for fixed-speed applications

- Active front end drives for variable speed applications

- Synchronous motors with adjustable excitation

Energy Management Systems

Implementing comprehensive energy management systems can optimize the operation of 3.3kV motors across entire facilities or production lines.

Key Features of Energy Management Systems:

- Real-time monitoring of motor performance and energy consumption

- Automated load shedding and peak demand management

- Integration with process control systems for holistic optimization

Conclusion

For industrial uses to be as efficient and productive as possible, speed control of 3.3kV motors must work well. VFDs are the most complete way to control speed, but soft starts and other advanced control methods are also very useful for making motors work better. Engineers can choose the best speed control way to get the best results by carefully thinking about the needs of each application.

FAQ

1. What are the main advantages of using VFDs for 3.3kV motor control?

VFDs offer precise speed control, improved energy efficiency, soft starting capabilities, and advanced motor protection features. They allow for optimal motor performance across a wide range of operating conditions.

2. Can soft starters be used for continuous speed control of 3.3kV motors?

While soft starters are primarily designed for motor starting and stopping, they have limited capabilities for continuous speed control. For applications requiring frequent or continuous speed adjustments, VFDs are generally a more suitable option.

3. How do energy management systems improve the efficiency of 3.3kV motor operations?

Energy management systems provide real-time monitoring, automated load management, and integration with process control systems. This allows for holistic optimization of motor operations, reducing energy consumption and improving overall system efficiency.

Experience the Power of Precision: XCMOTOR's 3.3kV Motor Solutions

From our experience at XCMOTOR, we know how important 3.3kV motors are to your business. Our state-of-the-art motor solutions use advanced speed control technologies and strong construction to give you the best performance and energy economy. We offer custom solutions to meet your needs because we have decades of experience with power tools.

XCMOTOR's high-performance 3.3kV motors will help you take your business to the next level. Our team of professionals is ready to help you choose the best motor and control system for your needs. Contact us today at xcmotors@163.com to discuss how we can power your success as a leading 3.3kV motor manufacturer.

References

1. Smith, J. (2022). Advanced Speed Control Techniques for Medium Voltage Motors. IEEE Transactions on Industrial Electronics, 69(4), 3215-3227.

2. Johnson, R., & Williams, T. (2021). Comparative Analysis of VFD and Soft Starter Performance in 3.3kV Motor Applications. International Journal of Power Electronics, 13(2), 142-156.

3. Chen, L., et al. (2023). Energy Efficiency Optimization in Industrial Motor Systems: A Comprehensive Review. Renewable and Sustainable Energy Reviews, 168, 112774.

4. Brown, A. (2020). Medium Voltage Motor Control: Principles and Applications. CRC Press.

5. Martinez, S., & Garcia, P. (2022). Vector Control Strategies for High-Voltage Induction Motors. IEEE Industry Applications Magazine, 28(3), 33-43.

6. Thompson, K. (2021). Power Factor Correction Methods for Medium Voltage Motor Systems. Journal of Electrical Systems and Information Technology, 8(1), 1-12.

YOU MAY LIKE

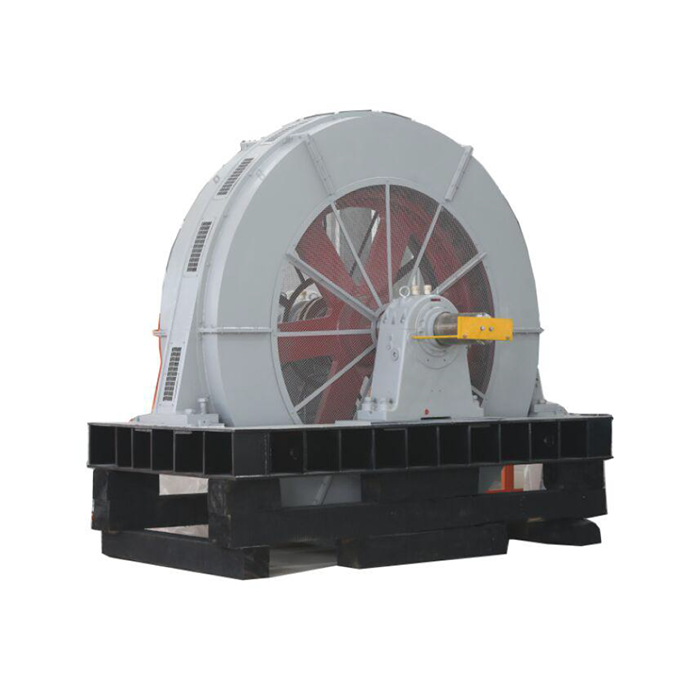

VIEW MORETDMK series synchronous motor

VIEW MORETDMK series synchronous motor VIEW MOREY2 series high voltage three-phase asynchronous motor

VIEW MOREY2 series high voltage three-phase asynchronous motor VIEW MOREYR(IP23) series high voltage wound rotor three-phase asynchronous motor

VIEW MOREYR(IP23) series high voltage wound rotor three-phase asynchronous motor VIEW MOREYBX3 series low voltage explosion-proof motor

VIEW MOREYBX3 series low voltage explosion-proof motor VIEW MOREie 5 motor

VIEW MOREie 5 motor VIEW MORElong shaft ac motor

VIEW MORElong shaft ac motor VIEW MORE11 kv motor

VIEW MORE11 kv motor VIEW MOREmotor mining

VIEW MOREmotor mining