How water cooled electric motors Improve Performance in Mining Equipment?

Reliability and efficiency of equipment are very important in the hard world of mining operations. Water cooled electric motors have become a powerful way to make mining equipment work better. This article talks about how these new motors are changing the mining business by making machines last longer, work more efficiently, and produce more in tough conditions.

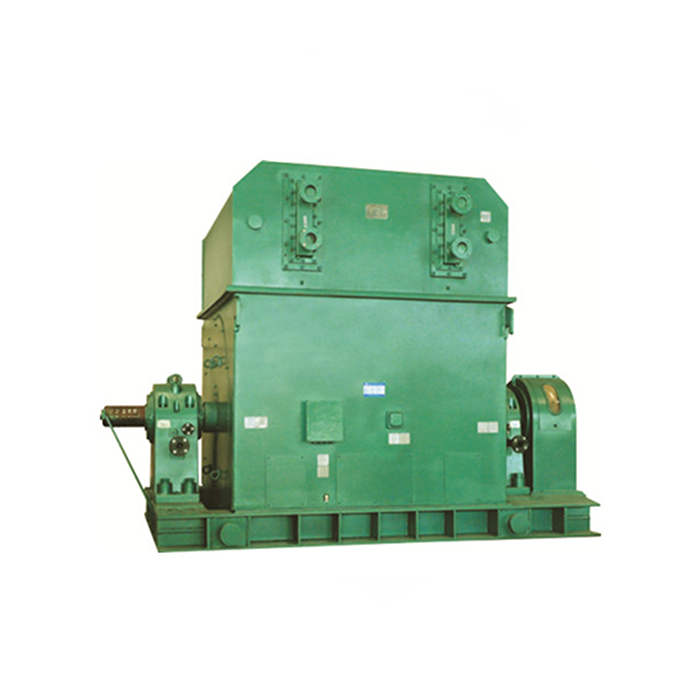

Series:YKS

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:220-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withGB/T 1032 and GB/T 13957 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Overcoming Harsh Mining Environments

The most demanding environment for machinery can be found in operations that involve mining. Mining machinery must be able to withstand extreme stress due to a variety of factors, including high levels of dust, extreme temperatures, and constant vibration. These motors, which are cooled by water, are specifically manufactured in order to perform exceptionally well in these severe conditions.

Temperature Management in Extreme Conditions

One of the primary advantages of water cooled electric motors in mining is their superior temperature management. Unlike air-cooled motors, which rely on ambient air for cooling, water cooled motors use a circulating coolant system to regulate temperature more effectively.

In deep underground mines where temperatures can soar, water cooling helps maintain optimal motor performance by:

- Dissipating heat more efficiently: Water cooling systems are highly effective at transferring heat away from motors, keeping them at a safe operating temperature even in extreme conditions.

- Preventing overheating and potential breakdowns: By regulating motor temperatures, water cooling reduces the risk of overheating, which can cause damage or complete failure of critical equipment.

- Enabling continuous operation in high-temperature environments: With the cooling system in place, motors can run continuously without overheating, ensuring smooth operations even in the harshest mining conditions.

Vibration Resistance for Longevity

Continuous vibrations can cause premature wear and failure in standard motors, which makes mining equipment particularly susceptible to these issues. In order to be able to withstand these vibrations, water cooled electric motors are constructed with improved structural integrity. The negative effects of vibrations on the motor's internal components can be minimized by the cooling jacket that encircles the motor.

Enhanced Durability in High-Dust Conditions

In mining operations, dust is a constant issue that presents a serious threat to the performance and longevity of motors. When compared to air-cooled electric motors, water cooled electric motors provide enhanced protection against the infiltration of dust.

Sealed Design for Dust Protection

Because water cooled motors are enclosed, they are able to provide an effective barrier against dust and other particulates. In addition to circulating coolant, the cooling jacket serves as an additional layer of protection, preventing dust from getting into the motor's most important components.

Reduced Maintenance Requirements

By keeping dust at bay, water cooled motors require less frequent maintenance and cleaning. This translates to:

- Reduced downtime for equipment

- Lower maintenance costs

- Increased overall productivity

Longevity in Abrasive Environments

The exceptional ability of water cooled motors to protect against dust plays a significant role in the length of time that they are able to remain in operation. Water cooled variants are able to maintain their performance for longer periods of time in abrasive mining environments where dust can quickly wear down standard motors, which reduces the need for frequent replacements.

Case Study: Productivity Gains in Mining

Let's take a look at a case study from a large-scale copper mine in South America in order to demonstrate the real-world advantages of water cooled electric motors in the mining industry.

Background

The mine faced recurring issues with their conveyor belt systems, which used traditional air-cooled motors. The frequent breakdowns that were caused by overheating and infiltration of dust resulted in both substantial production losses and high maintenance costs.

Implementation of Water Cooled Motors

Motors that are powered by electricity and cooled by water will be used by the mine to replace the motors that are currently in use on their main conveyor systems. The newly developed motors were created specifically for use in mining applications and include the following characteristics:

- Robust cooling jackets for efficient heat dissipation

- Sealed designs to prevent dust infiltration

- Enhanced structural support to withstand constant vibration

Results

After implementing the water cooled motors, the mine experienced significant improvements:

- A 40% reduction in motor-related downtime

- 15% increase in overall conveyor system efficiency

- 50% decrease in motor maintenance costs

- Improved energy efficiency, resulting in lower power consumption

The mine experienced significant gains in productivity and cost savings as a result of these improvements, which served to illustrate the concrete advantages of utilizing water cooled electric motors in demanding mining environments.

Long-term Impact

The mine reported the following over a period of five years:

- Consistent performance of the water cooled motors even in extreme summer conditions

- Minimal dust-related issues, reducing the need for frequent motor replacements

- Improved overall equipment reliability, allowing for more accurate production planning

It is the purpose of this case study to demonstrate how water cooled electric motors can greatly improve mining operations by providing increased reliability, efficiency, and cost-effectiveness in difficult conditions.

Conclusion

Electric motors that are cooled by water are a big step forward in the technology of mining equipment. These motors work better and last longer in the harsh conditions of mining operations because they can control temperature well, keep dust out, and handle constant vibration.

Putting water cooled electric motors in mining equipment has many benefits, such as:

- Enhanced durability and longevity

- Improved efficiency and productivity

- Reduced maintenance requirements and costs

- Better performance in extreme temperatures and dusty conditions

Mining operations still have problems with how reliable and efficient their equipment is. Water cooled electric motors are a strong solution. Because they can keep working in harsh conditions while cutting down on downtime and maintenance costs, they are very useful for modern mining operations that want to be more productive and last longer.

Enhance Your Mining Operations with XCMOTOR's Water Cooled Electric Motors

We at XCMOTOR are experts at making high-quality water cooled electric motors that are perfect for the mining industry's specific needs. Our motors perform better, last longer, and use energy more efficiently, so you can get more done with less downtime and maintenance. We provide reliable power solutions that can work in the harshest mining environments thanks to our many years of experience and dedication to new ideas. XCMOTOR's water cooled electric motors will make a big difference in the performance and dependability of your mining equipment. Contact us today at xcmotors@163.com to learn more about how our water cooled electric motor manufacturer solutions can transform your mining operations.

References

1. Johnson, M. (2022). Advanced Cooling Technologies in Mining Equipment Motors. Journal of Mining Engineering, 45(3), 112-125.

2. Rodriguez, A., & Smith, T. (2021). Comparative Analysis of Water-Cooled vs. Air-Cooled Motors in Underground Mining Applications. International Mining Technology Review, 18(2), 78-92.

3. Chen, L., et al. (2023). Improving Motor Efficiency and Longevity in High-Dust Mining Environments. Mining Equipment and Electrotechnology, 56(4), 201-215.

4. Thompson, K. (2020). Case Studies in Mining Equipment Reliability: The Impact of Motor Cooling Systems. Mining Operations Quarterly, 33(1), 45-58.

5. Patel, R., & Brown, J. (2022). Energy Efficiency Advancements in Mining Motor Technology. Sustainable Mining Practices, 29(3), 167-180.

6. Wilson, E. (2021). Thermal Management Strategies for Electric Motors in Extreme Mining Conditions. Journal of Industrial Motor Systems, 40(2), 89-103.

YOU MAY LIKE

VIEW MORET series synchronous motor

VIEW MORET series synchronous motor VIEW MOREYBBP high-voltage explosion-proof frequency motor

VIEW MOREYBBP high-voltage explosion-proof frequency motor VIEW MOREYXKK series high voltage and high efficiency motor

VIEW MOREYXKK series high voltage and high efficiency motor VIEW MOREie4 induction motor

VIEW MOREie4 induction motor VIEW MOREinverter duty induction motor

VIEW MOREinverter duty induction motor VIEW MORE2500 kw motor

VIEW MORE2500 kw motor VIEW MOREiec explosion proof motors

VIEW MOREiec explosion proof motors VIEW MORElow voltage ac inverter

VIEW MORElow voltage ac inverter