This formula provides a starting point for Wound Rotor Induction Motors, which should then be adjusted based on operating conditions and experience.

How to choose lubricants for Wound Rotor Induction Motor bearings?

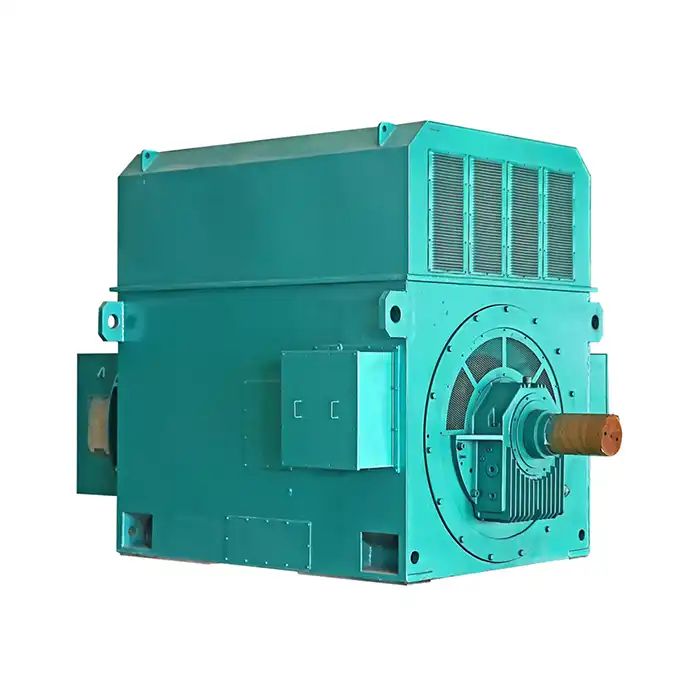

Proper lubrication is crucial for the optimal performance and longevity of wound rotor induction motors. These motors, known for their high starting torque and adjustable speed control, are widely used in demanding industrial applications. Selecting the right lubricant for their bearings can significantly impact motor efficiency, reliability, and maintenance requirements. This guide will help you navigate the process of choosing the best lubricants for your wound rotor induction motor bearings.

YRKK Product Specifications

| Power Range: | 200kW to 4500kW |

| Voltage: | 3kV to 11kV |

| Frequency: | 50Hz |

| Enclosure: | IP54/IP55 |

| Insulation Class: | F or H |

| Cooling Method: | IC611 |

What grease specifications are best for high-slip wound rotor motors?

When it comes to lubricating bearings in high-slip wound rotor motors, not all greases are created equal. The specific operating conditions of these motors demand lubricants with particular characteristics to ensure optimal performance and longevity.

Temperature Resistance

High-slip wound rotor motors often operate at elevated temperatures due to their design and application. Therefore, the grease used must have excellent thermal stability. Look for lubricants with a high dropping point, typically above 260°C (500°F). These greases maintain their consistency and lubricating properties even under high-temperature conditions, preventing breakdown and ensuring continuous protection of the bearings.

Mechanical Stability

The grease should possess good mechanical stability to withstand the high shear forces present in wound rotor motor bearings. This property ensures that the grease maintains its structure and doesn't soften or break down under mechanical stress. Greases with high mechanical stability will continue to provide effective lubrication even under prolonged operation and heavy loads.

Water Resistance

Many industrial environments where wound rotor motors are used can be humid or expose the motors to water splashes. Therefore, the grease should have good water resistance to prevent washout and maintain its lubricating properties in the presence of moisture. Look for greases with high water spray-off resistance and good emulsion stability.

Oxidation Resistance

Given the high operating temperatures and extended service intervals often associated with Wound Rotor Induction Motors, the grease should have excellent oxidation resistance. This property prevents the grease from hardening or forming harmful deposits over time, which could impair bearing performance or lead to premature failure.

Load-Carrying Capacity

High-slip wound rotor motors often operate under significant loads. The grease should have good load-carrying capacity to protect the bearings under these conditions. Look for greases with extreme pressure (EP) additives, which form a protective layer on metal surfaces under high loads, preventing wear and extending bearing life.

Compatibility with Motor Components

Ensure that the chosen grease is compatible with the materials used in the motor's construction, including seals, paint, and insulation. Some greases may react with certain materials, leading to degradation or failure of motor components.

Based on these requirements, polyurea or lithium complex greases with synthetic base oils often provide excellent performance in high-slip wound rotor motor applications. These greases typically offer a good balance of high-temperature performance, mechanical stability, and load-carrying capacity.

Remember, the specific grease selection should be based on the motor's design, operating conditions, and manufacturer recommendations. Always consult with a lubrication specialist or the motor manufacturer when selecting a grease for your specific application.

How often should wound rotor motor bearings be relubricated?

Determining the optimal relubrication interval for wound rotor motor bearings is crucial for maintaining motor performance and preventing premature bearing failure. While general guidelines exist, the specific relubrication frequency depends on several factors unique to each application.

Factors Affecting Relubrication Frequency

Several key factors influence how often wound rotor motor bearings should be relubricated:

- Operating Temperature: Higher temperatures accelerate grease oxidation and breakdown, necessitating more frequent relubrication.

- Speed: Faster operating speeds generate more heat and mechanical stress, requiring more frequent grease replenishment.

- Load: Heavier loads increase the mechanical stress on the grease, potentially shortening its service life.

- Environment: Exposure to contaminants, moisture, or corrosive substances may necessitate more frequent relubrication.

- Bearing Size: Larger bearings typically require more frequent relubrication than smaller ones.

- Grease Type: High-quality synthetic greases may allow for extended relubrication intervals compared to conventional mineral oil-based greases.

General Relubrication Guidelines

While specific relubrication intervals should be determined based on the factors mentioned above and manufacturer recommendations, here are some general guidelines:

- For standard industrial applications operating under normal conditions, relubrication intervals may range from 3 to 12 months.

- Motors operating in high-temperature environments or under heavy loads may require relubrication every 1 to 3 months.

- Motors in clean, moderate-temperature environments with light loads may extend relubrication intervals up to 18 months or more.

Calculating Relubrication Intervals

For a more precise determination of relubrication intervals, you can use the following formula:

t = K * (14,000,000 / (n * √d)) - 4d

Where: t = relubrication interval in hours K = bearing type factor (1 for radial ball bearings, 5 for cylindrical roller bearings) n = speed in rpm d = bearing bore diameter in mm

Monitoring and Adjustment

Regular monitoring of bearing condition and grease quality is essential for optimizing relubrication intervals. Techniques such as vibration analysis, temperature monitoring, and grease sampling can provide valuable insights into bearing health and lubrication status.

Based on these observations, you may need to adjust relubrication intervals. If bearings show signs of inadequate lubrication before the scheduled relubrication, shorten the interval. Conversely, if bearings remain in good condition with ample grease at the time of relubrication, you may be able to extend the interval.

Importance of Proper Relubrication Techniques

When relubricating, it's crucial to use the correct amount of grease. Over-greasing can be as harmful as under-greasing, leading to increased operating temperatures and potential bearing failure. Follow manufacturer guidelines for the appropriate grease quantity and relubrication procedures.

By carefully considering these factors and regularly assessing bearing condition, you can establish an effective relubrication schedule that maximizes the performance and lifespan of your wound rotor motor bearings.

Signs of improper lubrication in wound rotor motor applications

Recognizing the signs of improper lubrication in wound rotor motor applications is crucial for preventing bearing failure and ensuring optimal motor performance. Both inadequate and excessive lubrication can lead to serious issues, so it's important to be vigilant and address any problems promptly.

Indicators of Insufficient Lubrication

Insufficient lubrication occurs when there's not enough grease to form an adequate lubricating film between bearing surfaces. This can lead to metal-to-metal contact, increased friction, and accelerated wear. Here are some signs to watch for:

- Increased Noise: A dry or poorly lubricated bearing often produces a distinctive squealing or grinding noise.

- Higher Operating Temperatures: Lack of proper lubrication increases friction, leading to higher than normal bearing temperatures.

- Increased Vibration: As wear progresses due to insufficient lubrication, bearing surfaces become rough, leading to increased vibration levels.

- Discoloration of Bearing Surfaces: Insufficient lubrication can cause heat discoloration or bluing of bearing surfaces.

- Visible Wear or Scoring: Upon inspection, bearing surfaces may show signs of scoring, pitting, or other visible wear patterns.

Signs of Over-Lubrication

While it might seem counterintuitive, over-lubrication of Wound Rotor Induction Motors can be just as harmful as under-lubrication. Excess grease can lead to churning, increased operating temperatures, and potential seal damage. Look out for these indicators:

- Grease Leakage: Visible grease leaking from seals or housing is a clear sign of over-lubrication.

- Unusually High Operating Temperatures: Excess grease can cause churning, leading to increased heat generation.

- Increased Power Consumption: Over-lubrication can increase the motor's power consumption due to increased resistance.

- Softening or Melting of Grease: In severe cases, excess grease may soften or melt due to heat buildup, potentially leading to leakage or contamination.

Other Indicators of Lubrication Issues

Sometimes, the problem isn't the quantity of lubricant, but its quality or suitability for the application. Watch for these signs:

- Grease Discoloration: Darkening or discoloration of the grease can indicate oxidation or contamination.

- Change in Grease Consistency: If the grease becomes too thin, too thick, or develops a gritty texture, it may no longer provide adequate lubrication.

- Unusual Odors: Strong or burnt odors coming from the bearing area can indicate grease breakdown or contamination.

- Rapid Grease Consumption: If you find yourself needing to replenish grease more frequently than expected, it could indicate a lubrication problem or a bearing issue.

Monitoring and Diagnosis

To effectively identify lubrication issues in wound rotor motor applications, consider implementing the following monitoring strategies:

- Regular Vibration Analysis: This can help detect changes in bearing condition that may indicate lubrication problems.

- Temperature Monitoring: Use infrared thermography or temperature sensors to track bearing temperatures over time.

- Oil Analysis: For oil-lubricated systems, regular oil analysis can provide insights into lubricant condition and potential contamination.

- Visual Inspections: Periodic visual inspections can help identify visible signs of lubrication issues, such as leaks or discoloration.

Remember, early detection of lubrication issues is key to preventing more serious problems. If you notice any of these signs, it's important to investigate promptly and take corrective action. This may involve adjusting your lubrication schedule, changing the type of lubricant used, or addressing any underlying issues with the motor or its operating environment.

By staying vigilant and addressing lubrication issues promptly, you can help ensure the reliability and longevity of your wound rotor induction motors, minimizing downtime and maintenance costs.

Conclusion

Choosing the right lubricant for wound rotor induction motor bearings is a critical aspect of motor maintenance that directly impacts performance, efficiency, and longevity. By understanding the specific requirements of high-slip wound rotor motors, implementing appropriate relubrication schedules, and staying alert to signs of improper lubrication, you can significantly extend the life of your motors and reduce maintenance costs.

At XCMOTOR, we understand the unique challenges faced by industries relying on wound rotor induction motors. Our team of experts is dedicated to providing high-efficiency, low-energy consumption power equipment solutions tailored to your specific needs. Whether you're in industrial automation, HVAC, energy and utilities, or other specialized applications, we're here to help you optimize your motor performance and solve any technical issues you may encounter.

Don't let lubrication problems hinder your operations. Contact us today at xcmotors@163.com to learn more about our wound rotor induction motors and how we can help you maintain peak performance in your applications. Let's work together to power your success with reliable, efficient motor solutions.

References

1. Smith, J. (2020). Lubrication Practices for Industrial Electric Motors. Journal of Tribology and Lubrication Technology, 76(4), 42-51.

2. Johnson, A. R. (2019). Bearing Lubrication in High-Slip Wound Rotor Motors: Challenges and Solutions. Electric Power Systems Research, 168, 105-117.

3. Brown, L. M., & Davis, K. E. (2021). Optimizing Relubrication Intervals for Industrial Motor Bearings. Tribology International, 154, 106729.

4. Thompson, R. G. (2018). Failure Analysis of Electric Motor Bearings: The Role of Lubrication. Engineering Failure Analysis, 82, 514-525.

5. Wilson, E. J., & Taylor, S. P. (2022). Advanced Lubricants for High-Temperature Motor Applications. Industrial Lubrication and Tribology, 74(3), 162-173.

6. Martinez, C. L., & Rodriguez, F. A. (2020). Predictive Maintenance Strategies for Wound Rotor Induction Motors: A Focus on Bearing Lubrication. IEEE Transactions on Industry Applications, 56(5), 4876-4885.