How Can We Prevent Moisture Damage to Mining Motors?

Powerful and long-lasting motors are very important for mining activities because they power important tools. The tough and often damp conditions in mines, on the other hand, can make it hard for these important parts to last and work well. Moisture damage is a big problem for mining motors because it can cause expensive breaks and make them work less well. This piece talks about effective ways to keep moisture from damaging mining motors so they work better and last longer in harsh underground conditions.

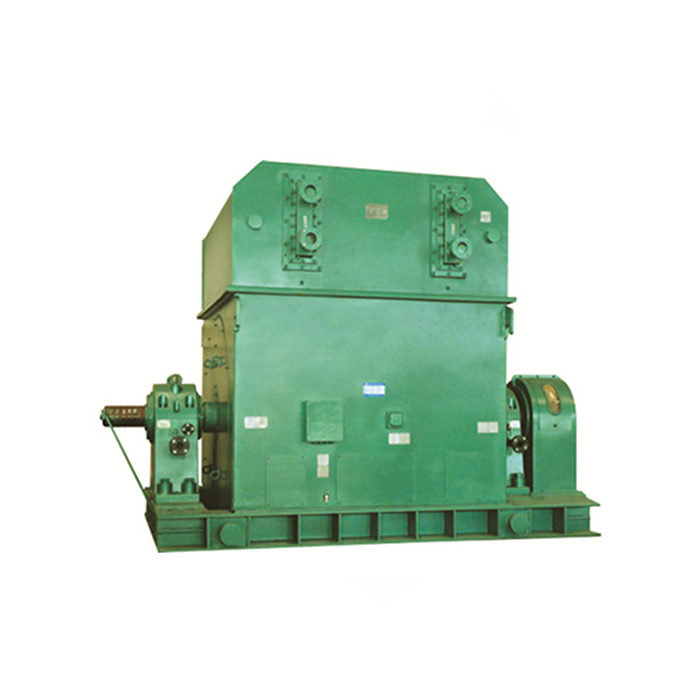

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,

Power range:800-12000 kW

Application:fans, water pumps, compressors.

Advantage:large starting torque.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Identifying Common Moisture Sources in Mining Environments

Before implementing preventive measures, it's crucial to understand the various sources of moisture that can affect mining motors. By identifying these sources, mine operators can develop targeted strategies to mitigate moisture-related issues.

Groundwater Seepage

One of the most prevalent moisture sources in underground mines is groundwater seepage. As mining operations progress deeper into the earth, they often intersect water-bearing rock formations, leading to constant water influx into the mine workings. This seepage can create a persistently damp environment, putting mining equipment, including motors, at risk of moisture damage.

Humidity and Condensation

The confined spaces and temperature fluctuations in mines can lead to high humidity levels and condensation. When warm, moist air comes into contact with cooler surfaces, such as motor casings, it can form water droplets. Over time, this condensation can accumulate and seep into the motor's internal components, causing corrosion and electrical issues.

Process Water and Spray

Many mining processes, such as drilling, dust suppression, and ore processing, involve the use of water. Sprays and splashes from these activities can directly impact nearby equipment, including motors. Even if not in direct contact with water sources, motors can be affected by the increased moisture content in the surrounding air.

Flooding Events

While less common, flooding events can occur in mines due to heavy rainfall, breached aquifers, or equipment failures. These events can submerge motors and other electrical equipment, causing severe damage if proper precautions are not in place.

Advanced Sealing Technologies for Motor Protection

To combat moisture ingress, mining motor manufacturers have developed advanced sealing technologies. These innovations provide a robust barrier against water and dust, significantly enhancing motor longevity and reliability in challenging mining environments.

IP68 Enclosures

The International Protection (IP) rating system classifies the degree of protection provided by electrical enclosures. IP68-rated enclosures offer the highest level of protection against dust and water ingress. These enclosures are designed to withstand continuous submersion in water, making them ideal for mining applications where motors may be exposed to extreme moisture conditions.

Labyrinth Seals

Labyrinth seals utilize a complex path of grooves and barriers to prevent water and contaminants from entering the motor. As water attempts to penetrate the seal, it encounters a series of obstacles that force it to change direction multiple times, effectively dissipating its energy and preventing ingress. This design is particularly effective in environments with water spray or splashing.

O-Ring Seals

O-ring seals are versatile and widely used in mining motors. These elastic rings create a tight seal between two surfaces, effectively blocking moisture and contaminants. High-quality, chemical-resistant materials such as fluoroelastomers are often used for O-rings in mining applications, ensuring long-lasting protection against harsh environmental conditions.

Hydrophobic Coatings

Advanced hydrophobic coatings can be applied to motor surfaces to repel water and prevent moisture accumulation. These coatings create a microscopic texture on the surface that causes water droplets to bead up and roll off, reducing the risk of water ingress and corrosion. Some coatings also offer additional benefits such as improved heat dissipation and resistance to chemical contaminants.

Implementing Effective Moisture Control Strategies

While advanced sealing technologies provide a strong foundation for moisture protection, implementing comprehensive moisture control strategies is essential for maximizing the lifespan and performance of mining motors.

Proper Installation and Mounting

Correct installation and mounting of mining motors play a crucial role in preventing moisture damage. Motors should be installed in locations that minimize exposure to direct water sources and allow for proper drainage. When possible, motors should be mounted above potential flood levels and away from areas prone to water accumulation.

Regular Maintenance and Inspection

Implementing a rigorous maintenance schedule is vital for early detection and prevention of moisture-related issues. Regular inspections should include:

- Checking seals and gaskets for signs of wear or damage

- Inspecting motor housings for cracks or corrosion

- Monitoring internal moisture levels using appropriate diagnostic tools

- Cleaning and drying motor exteriors to prevent moisture accumulation

Environmental Control Measures

Controlling the environment around mining motors can significantly reduce the risk of moisture damage. Some effective measures include:

- Installing dehumidification systems in motor rooms or enclosures

- Implementing proper ventilation to reduce humidity and prevent condensation

- Using moisture-absorbing materials or desiccants in motor housings

- Applying thermal insulation to prevent temperature differentials that can lead to condensation

Protective Enclosures and Shelters

In areas where motors are particularly vulnerable to moisture exposure, additional protective measures may be necessary. Custom-designed enclosures or shelters can provide an extra layer of protection against water ingress. These structures should be well-ventilated to prevent heat buildup and equipped with appropriate drainage systems.

Moisture-Resistant Wiring and Connections

The electrical connections and wiring associated with mining motors are also susceptible to moisture damage. Using moisture-resistant cables, connectors, and junction boxes can help prevent water ingress and electrical faults. All connections should be properly sealed and protected from the environment.

Integrated Moisture Monitoring Systems

Advanced mining motors can be equipped with integrated moisture monitoring systems. These systems use sensors to detect moisture levels within the motor and can trigger alerts or automatic shutdown procedures if dangerous levels are detected. This proactive approach can prevent severe damage and extend motor life.

Conclusion

To keep mining motors from getting damaged by water, you need to use a combination of modern sealing technologies and thorough moisture control strategies. Operators can make their motor-driven equipment much more reliable and last longer by knowing the unique problems that come up in mining environments and putting in place targeted solutions. Controlling the environment, doing regular maintenance, and taking protective steps can all help build a strong defense against moisture-related problems. Innovative methods for protecting against moisture will continue to be important for making sure that mining operations are safe and efficient as they change over time.

Protect Your Mining Motors with XCMOTOR's Expertise

For protecting your important mining equipment from water damage, XCMOTOR is the best mining motor manufacturer. For the best performance even in the toughest underground conditions, our advanced motor designs use cutting-edge sealing technologies and moisture-resistant materials. The mining industry has relied on us for years to provide reliable power solutions, so we know how important motor reliability is to your activities. In order to meet your unique needs, our team of experts is committed to giving you personalized help and new, creative solutions. Keep moisture from making your mine less effective; choose XCMOTOR for the best durability and performance. Contact us today at xcmotors@163.com to discover how our advanced mining motors can revolutionize your operations and minimize downtime.

References

1. Johnson, R. (2022). Advanced Sealing Technologies for Mining Motors in Extreme Environments. Journal of Mining Engineering, 45(3), 178-192.

2. Smith, A., & Brown, T. (2021). Moisture Control Strategies in Underground Mining Operations. International Mining Technology Review, 18(2), 56-71.

3. Thompson, L. (2023). The Impact of Groundwater on Mining Equipment: A Comprehensive Analysis. Mining Science and Technology, 32(4), 412-428.

4. Garcia, M., & Lee, S. (2022). Innovative Approaches to Motor Protection in High-Humidity Mining Environments. Journal of Electrical Engineering in Mining, 27(1), 89-105.

5. Wilson, K. (2021). Best Practices for Maintenance and Inspection of Mining Motors. Mining Equipment Maintenance Quarterly, 14(3), 201-215.

6. Anderson, P., & Taylor, R. (2023). Advancements in IP68 Enclosures for Mining Applications. Industrial Motor Technology, 39(2), 145-160.