Fire-resistant mining motor components play a pivotal role in elevating safety standards within the mining industry. Mining motors, designed to operate in harsh and hazardous environments, face risks such as electrical faults and overheating that could potentially trigger fires. Incorporating fire-resistant materials and components mitigates these risks effectively by minimizing ignition sources and containing potential electrical fires. This level of protection ensures continuance of operations with reduced downtime, safeguards personnel, and protects expensive equipment. Through enhanced thermal stability and flame resistance, these specialized mining motors improve workplace safety profoundly among underground and surface mining applications.

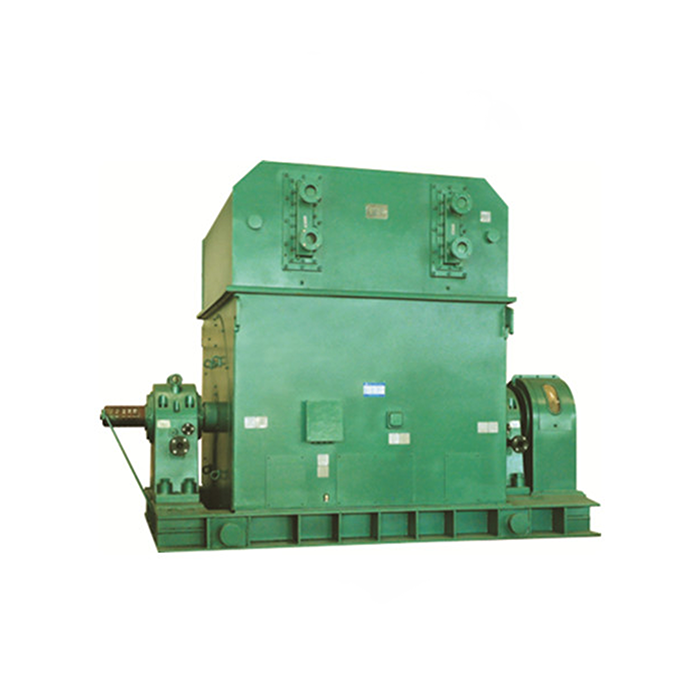

Series:T

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,

Power range:800-12000 kW

Application:fans, water pumps, compressors.

Advantage:large starting torque.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Mining Motors: Withstands Harsh Conditions

Mining motors serve as the backbone for a wide array of mining equipment. Unlike standard industrial motors, they are engineered to withstand adverse conditions including dust infiltration, moisture exposure, extreme temperatures, and mechanical vibrations commonly encountered in mining environments. These motors power essential machinery such as fans that maintain ventilation, water pumps essential for dewatering, and compressors that provide pneumatic energy. Among various specifications, voltage ranges commonly include 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, and 10000V±5%, with power capacity spanning from 800 to 12000 kW, accommodating heavy-duty mining demands.

Mining motors are typically designed for low-speed operations—ranging between 150 to 500 RPM—and prioritize features such as rugged cast iron frames and reinforced bearings. These characteristics ensure durability against the high-impact and continuous usage scenarios. Appreciating the technical details and operational requirements helps mining engineers and maintenance specialists select the correct motor variant to maximize safety and reliability within their specific mining context.

Benefits of Fire-Resistant Components in Mining Motors

The incorporation of fire-resistant components within mining motors represents a crucial advancement for operational safety. Mining operations are inherently exposed to flammable gases, combustible dust, and electrical hazards. Using fire-resilient materials minimizes ignition risks, safeguarding both human life and assets.

Here are the core advantages of this device:

- Fire retardant insulation materials in windings prevent thermal degradation, reducing chances of electrical faults that lead to fires. This ensures longer motor life in moist and corrosive mine shaft environments.

- Robust bearings such as SKF, NSK, or FAG—removable according to customer needs—contribute to smooth motor function, reducing friction-generated heat, which could otherwise ignite surrounding materials.

- Special coatings on components inhibit corrosion and combustion propagation, crucial where mineral dust accumulates on electrical parts.

- Large starting torque ensures rapid motor engagement without causing electrical spikes prone to short-circuiting.

These advantages can effectively solve production problems often caused by motor-related fire hazards, significantly decreasing maintenance costs and enhancing operational uptime within mining settings.

Advances in Mining Motor Technology

Recent technological advancements have transformed mining motor safety and performance. Improved electrical insulation systems, advanced rotor balancing through CNC machinery, and enhanced cooling methods such as IC01 enable motors to operate efficiently even under intense load.

Sustainability remains a core focus; modern designs optimize energy consumption, integrating power factors ≥ 0.85 that reduce wasteful power usage. Developments in moisture-resistant coatings extend the operational life of motors under damp conditions, a frequent challenge in underground mines.

Certification standards such as ISO 9001:2015, IEC Ex certification for explosive atmospheres, and China Compulsory Certification (CCC) provide assurance regarding compliance with global safety and quality norms. Anticipated future directions emphasize integration with smart monitoring systems for predictive maintenance, further mitigating fire risks through real-time diagnostics.

Selecting the Right Mining Motor for Your Needs

Selecting an appropriate mining motor requires aligning technical specifications with intended application scenarios. Key factors include:

- Power rating suitability for the intended load, ranging between 800 and 12000 kW, ensures efficiency and prevents motor overload.

- Voltage compatibility with existing infrastructure—covering levels such as 3000V±5% to 10000V±5%—prevents electrical mismatches that can cause faults.

- Reinforced protection class (IP20) and insulation class F provide a standard for dust ingress resistance and thermal endurance.

- The reputability of motor brand and availability of customizable components like SKF, NSK, and FAG bearings support long-term maintenance and operational reliability.

Considering these factors reduces hesitation during procurement and facilitates confidence in the motor's capacity to meet safety and performance demands under mining conditions.

Integrating Fire-Resistant Motors into Your Operations

Achieving effective integration of fire-resistant mining motors requires a combination of strategic planning and ongoing maintenance. Establishing protocols that prioritize regular inspection of fire-resistant components ensures early detection of potential faults.

Case studies reveal that enterprises adopting fire-resistant motors benefit from reduced incidents of motor-related fires, resulting in safer work environments and prolonged equipment lifespan. Employing trained technicians familiar with the unique needs of these motors prevents improper installation or handling that could compromise safety features.

Practical tips include ensuring compatibility with auxiliary safety measures such as explosion-proof enclosures and conducting routine performance tests under operational loads to verify cooling system effectiveness.

Company Overview and Product Offerings

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., operating as XCMOTOR, stands at the forefront of delivering robust mining motor solutions tailored to stringent safety and efficiency standards. Our products are rigorously engineered to persist under the toughest underground conditions characterized by dust, vibration, and moisture.

Our mining motors boast power ranges from 800 kW up to 12000 kW and voltage options spanning from 3000V±5% to 10000V±5%. Designed with large starting torque capabilities, they excel in powering fans, water pumps, and compressors, critical for mining applications. The rugged cast iron frame construction combined with advanced moisture-resistant insulation extends operational life significantly.

We prioritize customer preferences, offering customizable bearing replacements using trusted brands like SKF, NSK, and FAG. Our strict production and quality assurance protocols incorporate CNC balancing, multiple-stage inspections, and adherence to internationally recognized certifications including ISO 9001:2015 and IEC Ex.

Dedicated to comprehensive support, XCMOTOR ensures fast delivery, free shipping, and responsive technical assistance even during weekends, making us a reliable partner for mining enterprises seeking durable and fire-resistant motor solutions.

Conclusion

Fire-resistant mining motors represent a vital investment toward enhancing operational safety and efficiency in the mining sector. Their tailored design caters to the extreme conditions miners face daily, reducing fire hazards through innovative materials and construction. By understanding motor specifications and integration requirements, mining operations can select and implement products that minimize risks while optimizing performance. XCMOTOR's premium mining motors embody these safety advancements, empowering mining enterprises to maintain uninterrupted productivity with confidence.

Frequently Asked Questions (FAQ)

Q1: What are the key benefits of using fire-resistant mining motors?

A: Fire-resistant mining motors substantially reduce the risk of electrical fires by utilizing specialized materials that resist ignition and limit fire propagation. This enhances workplace safety, lowers equipment downtime, and prolongs motor lifespan under demanding conditions.

Q2: How do fire-resistant components enhance mining motor safety?

A: Components such as fire-retardant coil insulation, corrosion-resistant coatings, and robust bearings lower thermal hotspots and energy loss, preventing faults that could lead to combustion. These features stabilize motor performance under adverse mining environments, safeguarding both personnel and machinery.

Q3: What should I consider when purchasing a mining motor?

A: Essential considerations include matching the motor's power and voltage specifications with operational requirements, verifying compliance with protection and insulation classes, ensuring availability of quality replacement parts, and selecting mining motor manufacturers with stringent quality controls and certifications.

Where to Buy mining motor

Procuring a mining motor that balances durability, safety, and efficiency is key to robust mining operations. XCMOTOR provides a comprehensive range of high-quality mining motors with specifications such as power ranges from 800 to 12000 kW and versatile voltage options conforming to your technical needs. Equipped with advanced fire-resistant components and customizable bearings from SKF, NSK, and FAG, our motors assure reliability in the most demanding mining environments. For expert guidance and tailored solutions, contact us at xcmotors@163.com. Our experienced team is ready to assist you in selecting the ideal mining motor to enhance your operational safety and productivity.

References

- IEC Publication 60079-0: Equipment for Explosive Atmospheres – General requirements.

- National Fire Protection Association (NFPA) 70: National Electrical Code.

- IEEE Standard 112-2017: Methods for Mechanical and Electrical Testing of Electric Motors.

- “Advances in Fire-Resistant Electrical Motors for Hazardous Locations,” Journal of Mining Safety Engineering, 2022.

- ISO 9001:2015 Quality Management Systems – Requirements, International Organization for Standardization.

- “Enhancing Mining Equipment Safety Through Electrical Motor Innovation,” Mining Technology Review, 2023.