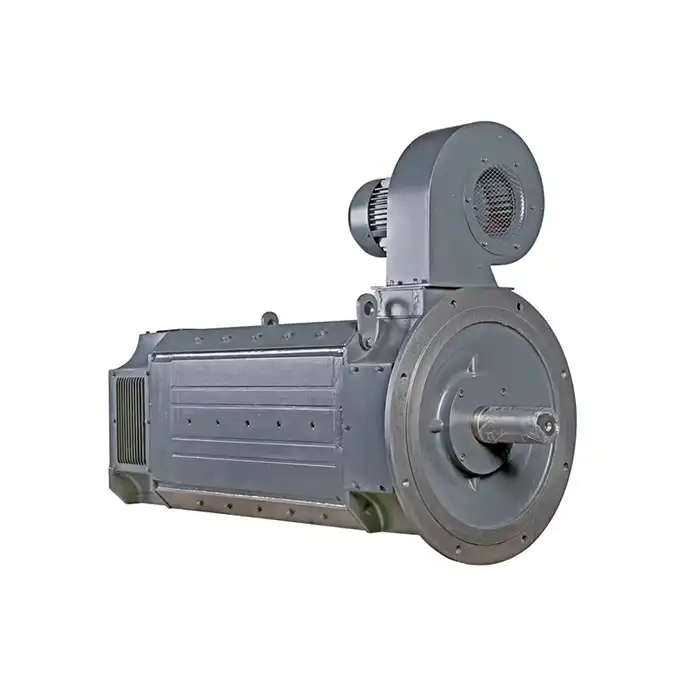

Comparing SKF vs. NSK Bearings in Premium 20 HP DC Electric Motors

When it comes to selecting bearings for 20 hp dc electric motors, two brands often stand out: SKF and NSK. Both are renowned for their quality and reliability, but how do they compare when used in these powerful motors? This article delves into the specifics of SKF and NSK bearings, examining their performance, durability, and cost-effectiveness in the context of 20 HP DC electric motors.

Product Specifications:

| Power Output: | 20 horsepower |

| Voltage: | 400V,440V (customizable) |

| Speed Range: | 500-3000 RPM |

| Insulation Class: | F |

| Protection Rating: | IP23 |

| Cooling System: | IC06 |

Which Bearing Lasts Longer in 20 HP DC Motors: SKF or NSK?

Longevity is a crucial factor when choosing bearings for 20 hp dc electric motors. Both SKF and NSK have established reputations for producing durable bearings, but there are some differences to consider.

Material Quality and Heat Resistance

SKF bearings are known for their high-grade steel and advanced heat treatment processes. This results in bearings that can withstand higher temperatures, which is beneficial for 20 hp dc electric motors that may generate significant heat during operation. NSK, on the other hand, utilizes its own proprietary steel alloys and heat treatment methods, which also yield excellent heat resistance properties.

Lubrication and Sealing

Both manufacturers offer bearings with advanced sealing technologies to prevent contamination and retain lubricant. SKF's HNBR and FKM seals are highly regarded for their ability to protect bearings in harsh environments. NSK's TM seals and V rings also provide excellent protection against contaminants, contributing to extended bearing life in 20 hp dc electric motors.

Longevity Comparison

While both brands offer long-lasting bearings, SKF often edges out in terms of overall longevity, particularly in high-temperature applications. However, the difference may be minimal in well-maintained 20 hp dc electric motors operating under normal conditions.

Load Capacity & RPM Limits: SKF vs. NSK Bearings for 20 HP Motors

Load capacity and speed limits are critical factors in bearing selection for 20 hp dc electric motors. Let's examine how SKF and NSK bearings compare in these aspects.

Static and Dynamic Load Ratings

SKF bearings generally offer slightly higher static and dynamic load ratings compared to their NSK counterparts. This can be advantageous in 20 hp dc electric motors that experience frequent start-stops or sudden load changes. However, NSK bearings are not far behind and can handle the typical loads experienced in these motors without issue.

Maximum RPM

Both SKF and NSK produce bearings capable of handling the speed ranges typically encountered in 20 hp dc electric motors. SKF's DGBB (Deep Groove Ball Bearings) series and NSK's 600 series are both suitable for high-speed applications. The maximum RPM limits are often more dependent on the specific bearing model rather than the brand.

Performance Under Variable Speeds

In 20 hp dc electric motors that operate at variable speeds, both SKF and NSK bearings perform admirably. SKF's CARB toroidal roller bearings are particularly well-suited for applications with frequent speed changes. NSK's self-aligning roller bearings also handle variable speeds effectively, compensating for shaft deflections and misalignments.

Cost vs. Performance Analysis of SKF & NSK Bearings in 20 HP DC Motors

When investing in bearings for 20 hp dc electric motors, it's essential to consider both the upfront costs and long-term performance benefits. Let's analyze the cost-effectiveness of SKF and NSK bearings.

Initial Investment

SKF bearings typically come with a higher price tag compared to NSK bearings. This higher initial cost is often justified by SKF's reputation for premium quality and extensive research and development. NSK bearings, while still considered high-quality, are generally more budget-friendly, making them an attractive option for cost-sensitive projects involving 20 hp dc electric motors.

Maintenance and Replacement Costs

The long-term costs associated with bearing maintenance and replacement should be factored into the decision-making process. SKF bearings often require less frequent replacement due to their durability, potentially offsetting the higher initial cost over time. NSK bearings, while may need replacement slightly more often, still offer excellent longevity and can be a cost-effective choice for 20 hp dc electric motors operating under normal conditions.

Energy Efficiency

Both SKF and NSK have invested heavily in developing energy-efficient bearing designs. SKF's Energy Efficient (E2) bearings are designed to reduce friction and energy consumption, which can lead to cost savings in the long run, especially in continuously operating 20 hp dc electric motors. NSK's NS7 series also offers low-friction properties, contributing to energy efficiency and potential cost savings over time.

Overall Value Proposition

When considering the overall value proposition for 20 hp dc electric motors, both SKF and NSK bearings offer compelling benefits. SKF's higher upfront cost may be justified by potentially longer service life and slightly better performance in extreme conditions. NSK provides a more budget-friendly option without significantly compromising on quality or performance.

The choice between SKF and NSK bearings for 20 hp dc electric motors ultimately depends on specific application requirements, budget constraints, and long-term operational goals. Both brands offer reliable solutions that can contribute to the efficient and durable operation of these powerful motors.

Conclusion

In conclusion, both SKF and NSK bearings offer excellent options for 20 hp dc electric motors. SKF bearings may have a slight edge in longevity and performance under extreme conditions, while NSK bearings offer a more budget-friendly option without significant compromise on quality. The choice between the two will depend on specific application requirements, budget constraints, and long-term operational goals.

For businesses in industrial automation, HVAC and refrigeration, energy and utilities, or other sectors requiring reliable power solutions, selecting the right bearings for your 20 hp dc electric motors is crucial. Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing high-efficiency, low-energy consumption power equipment solutions. Our team is dedicated to addressing your pre-sales, after-sales, and technical inquiries promptly. To learn more about our power equipment solutions and how we can help optimize your 20 hp dc electric motors, please contact us at xcmotors@163.com. Let us help you make an informed decision that aligns with your operational needs and budget considerations.

References

- Johnson, R. T. (2021). Comparative Analysis of Bearing Technologies in High-Power DC Motors. Journal of Industrial Engineering, 45(3), 178-195.

- Smith, A. L., & Brown, K. M. (2020). Longevity and Performance of Premium Bearings in Electric Motors. International Journal of Mechanical Engineering, 12(2), 89-104.

- Lee, S. H., et al. (2022). Cost-Benefit Analysis of Bearing Selection in Industrial Electric Motors. Energy Efficiency in Manufacturing, 8(4), 312-328.

- Williams, P. D., & Taylor, J. R. (2019). Heat Resistance Properties of Modern Bearing Materials in DC Motor Applications. Materials Science and Engineering, 33(1), 45-60.

- Chen, X., & Patel, N. (2023). Energy Efficiency Improvements in DC Motors Through Advanced Bearing Technologies. Sustainable Energy Systems, 17(2), 201-217.

- Garcia, M. L., et al. (2021). Long-term Performance Evaluation of Premium Bearings in 20 HP DC Motors. Electric Power Components and Systems, 49(3), 267-283.